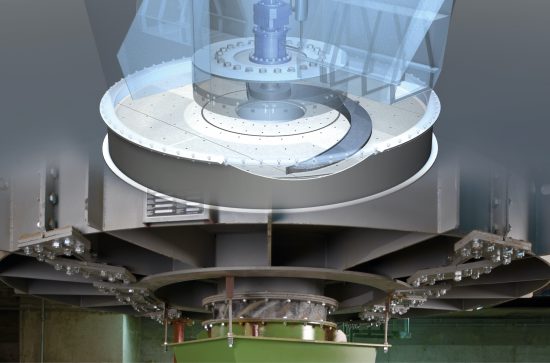

Wagon Unloading Systems & Wagon Tipplers / Rail Car Dumpers

Specialised and automated Wagon Unloading Systems for the most varied of materials and localised conditions

Careful planning in the design of Wagon Unloading Systems, of which Wagon Tipplers / Rail Car Dumpers are the core component, is very important. Capacity, material, geographic and climatic conditions as well as the desired degree of automation, and environmental and legal regulations, are decisive factors in finding the right concept for cost-effective operation.

Since 2010 SCHADE Lagertechnik (member of the AUMUND Group) has been responsible for the design, sales and project management of Wagon Tipplers. Prof. Heinrich Aumund who was one of the pioneers, applying for his first patent in 1929, developed Wagon Tipplers for bulk materials such as coal and created the basis for a technology that has been constantly improved over the years by the SCHADE design office in Bristol/GB.

Some of the requirements for Wagon Unloading Systems have changed dramatically since the early beginning, such as being able to deal flexibly with different types of wagons and with almost fully automated operation. The SCHADE Wagon Unloading specialists confer closely with their customers to find the optimum solution in terms of material, volume and local situation for each application. Recently, a significant growth factor is the development of business with Wagon Unloading Systems especially in Russia, the CIS countries as well as in South America.

Video: Three Wagons Unloaded at a Time (Taman Seaport, Russia)

SCHADE Stockyards and Blending Beds (PDF)

SCHADE Performance in Stockyard Technologies (PDF)

SCHADE Wagon Tipplers – Three Wagons Unloaded at a Time (Taman Seaport, Russia)

Products & Systems

Discharge Systems

Bucket Elevators

Chain Conveyors

Apron Feeders

SAMSON® Material Feeder (fixed)

Samson® Material Feeders (mobile)

Pan Conveyors

Telescopic Spouts

Circular Storage

Longitudinal Storage

Stackers, Reclaimers & Combined Machines

Wagon Unloading Systems & Wagon Tipplers

Eco Hoppers

Shiploader