AUMUND Fördertechnik GmbH

Visionary solutions for conveying and storing abrasive and other challenging bulk materials

AUMUND Fördertechnik GmbH, with over 95 years’ success, is one of the leading international specialists for cost-effective and innovative conveying technologies. Since its beginnings in 1922, the Rheinberg company has been supplying tailor-made conveying and storage technology for the most varied of bulk materials.

With nearly 24,000 references in around 150 countries in many key industries, such as cement, lime and gypsum, iron, steel and aluminium, in power plant technology, foundries, bulk materials processing, chemicals and fertiliser, as well as in the transportation and conveying of alternative fuels, AUMUND is one of the most experienced and sought-after suppliers of Belt and Chain Bucket Elevators, Pan Conveyors, stationary and mobile Material Feeders, Chain Conveyors, Discharge Systems and Loading Solutions for a wide variety of bulk materials from the quarry through the production process to loading onto truck, rail or ship.

Three generations, three emphases

AUMUND has been synonymous with technological innovation in the conveying of hot and abrasive materials for over 95 years, setting international standards with its exceptionally reliable products.

Heinrich Aumund, the founder

The plan for company founder Professor Heinrich Aumund was that he carry on his parents’ farm near Bremen. However, from an early age he succumbed to a fascination with technology, and went on an academic career path, studying mechanical engineering and physics. He specialised in applications for transportation in coal mining in the Ruhr area and the Lower Rhineland, and as early as 1929 Heinrich Aumund’s development of a rail wagon tippler was patented.

But at the age of 36, as the youngest full professor at Gdansk University of Technology, Heinrich Aumund devoted himself to the education of young people. Alongside his duties as a professor, Heinrich Aumund, who had patent rights in almost all industrialised nations on earth by that time, ventured into setting up a business. In 1922 in Berlin he founded AUMUND Fördererbau GmbH as a design and sales office, laying the foundation stone for the success of the AUMUND Group today. From now on, customers were not only to be found in mining or iron and steel but also in many other industries.

Günter Claus Aumund, the second generation

In 1951, Günter Claus Aumund, the son of Heinrich, took over the engineering firm. Over the following two years, AUMUND Fördererbau GmbH relocated to Homberg, today a suburb of Duisburg. But what Günter Claus Aumund really wanted was his own production facilities, which finally the young proprietor found in 1955 in Pötters former agricultural machinery works in Rheinberg in the Lower Rhineland.

Günter Claus Aumund, enthusiastically supported by his wife Ilse, bought five land parcels in a foreclosure auction on 12th November 1955, and this started the tremendous growth from local mining supplier to today’s internationally operating Group of Companies. Production in its own works started in 1956. Thanks to the continually growing success with AUMUND conveying technology, the works, production capacities and services have been expanding exponentially. During the mining crisis, which started at the beginning of the 60s, AUMUND Fördererbau GmbH suffered loss of turnover from its main customer base. However, alongside mining, AUMUND started to supply to the internationally renowned cement industry which was creating increased demand and therefore additional income.

Franz-W. Aumund, the third generation

Franz-W. Aumund leads the Group of Companies with currently around 500 employees all over the world as the third generation Managing Shareholder. His name has been associated for the past 50 years with building up an international sales network for AUMUND, SCHADE and SAMSON products, and with the leadership of an internationally operating Group of Companies.

In addition to the international cement industry the AUMUND Group serves customers all over the world in iron, steel, aluminium, foundries, power plant technology, mining and minerals, chemicals and fertiliser, ports and loading, and in all industries which have chosen alternative fuels as energy sources for their thermal processes.

Individual, technically sophisticated products in conveying and storage technology have contributed to the AUMUND Group’s excellent international market leadership position.

Cement

The range of AUMUND machines for conveying and storage of bulk materials is wide but very specific, covering almost all process stages in cement manufacture, such as the exploitation and subsequent processing of raw materials, kiln feeding, clinker grinding, conveying and storage, as well as clinker loading.

Minerals

AUMUND products have been used internationally in minerals and raw materials processing for decades, predominantly operating where bulk materials are to be conveyed and stored. As AUMUND machines are ideal for materials with challenging properties such as abrasiveness or cohesiveness, the range of minerals and raw materials handled is wide.

Metallurgy

One key focus of AUMUND conveying technology is a multitude of applications in the iron, steel and aluminium industries as well as in foundries. Tailor-made solutions coupled with decades of international experience make AUMUND one of the most proficient and reliable partners of its customers.

A particular area of expertise and command of market leadership is to be seen in direct reduction and smelting, feeding DR, discharge of hot material, direct charging, sinter and coking plants, coke dry quenching (CDQ), arc furnace feeding, scrap conveying, transportation of hot pellets, briquetting, HBI cooling as well as material intake and output.

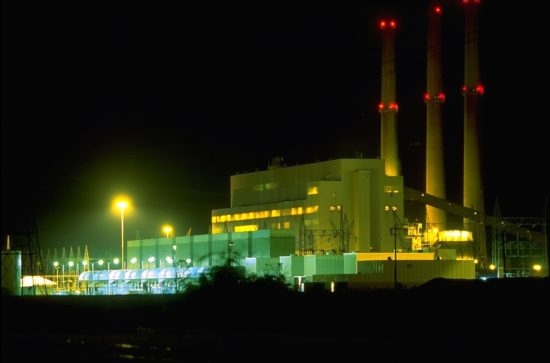

Power Plants

AUMUND machines are classed as essential in many areas of a power plant, starting with the intake of coal, RDF, biomass or limestone, continuing through the process, whether grate firing, coal dust firing or fluidised bed combustion (CFB/SFB) and culminating in the output of gypsum, ash, slag and dust.

Chemicals Industry

Over 95 years of experience and broad know-how in the most varied of industries all over the world positions AUMUND as a reliable partner to serve the specific requirements of the chemicals industry. A particular emphasis can be seen in applications of AUMUND machines in the fertiliser industry. As the bulk materials in this sector are often corrosive, the equipment is frequently supplied in stainless steel.

Ports & Loading

AUMUND Telescopic Chutes are a technically sound, cost-effective and environmentally friendly solution in ports for intake and output of material from ship to truck or rail and vice versa.

Alternative Fuels

With growing requirements for alternative energy sources, there is an increasing need for conveying and storage equipment specific to these materials. The AUMUND Group started to focus on this growth market some time ago, and its efforts are being rewarded by excellent references in many areas.

All kinds of materials are made available to their respective processes by the use of products from AUMUND Fördertechnik. The variety of alternative energy sources is boundless. Some examples are waste from livestock farming and food production, wood chips, shredded plastic, sewage sludge and chipped tyres.

The main applications are silo feeding and discharge systems, stockyard and reclaim technology as well as mobile and stationary conveying and storage solutions in materials handling.

Process Optimisation and Conversions

Depending on the existing situation and required new performance data, the exchange of parts and components can contribute significantly to modernising and optimising the efficiency of the plant, and serve as a technological and cost-effective alternative to new equipment. AUMUND offers upgrades to its own conveying and storage equipment and to machines of other manufacturers.