Bucket Elevators

Cost-effective and reliable vertical conveying

With their proven quality, reliable operation, high conveying capacities, long service lifetime and low operating costs AUMUND Bucket Elevators have become a synonym for efficient vertical transport of any kind of bulk material. Dependent on material, application and local conditions, the Bucket Elevators are supplied either in central chain or belt design.

AUMUND Belt Bucket Elevators, Chain Bucket Elevators, Double Chain Bucket Elevators and Bucket Elevators with Gravity Discharge for handling all kinds of bulk materials such as:

- limestone

- aggregates

- clinker

- slag

- cement

- gypsum

- coal

- ores

- fly ash

and many others.

In accordance with the operating situation, the material to be transported and the required conveying capacities, AUMUND offers the appropriate Bucket Elevator Systems.

Belt Bucket Elevator type BWG

AUMUND Belt Bucket Elevators of the type BWG are equipped with specially developed steel cord belts which are long-lasting and can operate under temperatures of up to 150°C. The belt is turned precisely in the Bucket Elevator boot on a bar drum, and is kept exactly parallel by a parallel tensioning device.

Functions and characteristics

- Secure belt connection by clamping the belt ends in a casting compound box (clamping connection)

- Friction linings of the drive drum can be exchanged without opening the belt

- Range of conveying capacities from low to very high

- Lifting heights above 170m and sometimes even higher

- Conveying capacities of up to 2,400 mᵌ/h

- Compact bucket arrangement with very little space between

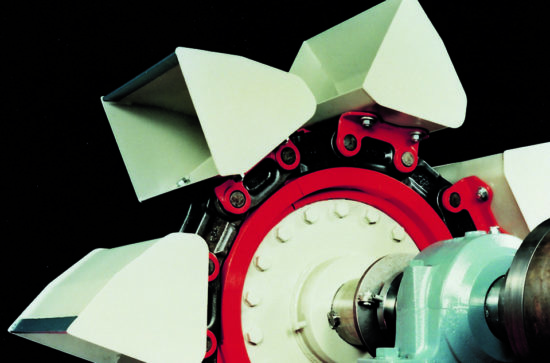

Chain Bucket Elevator type BWZ

AUMUND Bucket Elevators of the type BWZ are equipped with a forged central chain and are designed to convey all kinds of coarse, hot or abrasive bulk materials. In 24-hour continuous operation, conveying capacities of over 900 mᵌ/h are achieved at centre distances above 30m.

Functions and characteristics

- Conveying of bulk material at temperatures of up to 850°C

- Heat resistant up to 400°C

- Homogenous conveying flow with minimum spillage due to closely spaced buckets

- Simple and reliable bucket fixing (AUMUND patent) to maximise service lifetime

- Forged chain with lubricated labyrinth seal

- Silo and mill feeding applications

- Suitable for abrasive, hot, coarse and fine material

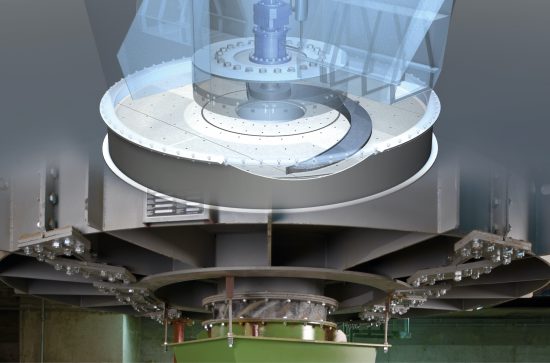

Double Chain Bucket Elevator type BWZ-D

For conveying capacities of over 1,800 mᵌ/h AUMUND has developed the Double Chain Bucket Elevator. The BWZ-D can be supplied with centre distances of over 90m. This Bucket Elevator is a pairing of two standard Bucket Elevators each with a central chain behind. Both bucket strands run over the same drive shaft which is supported in pillow block bearings and driven by double drive units.

Functions and characteristics

- Conveying capacities of more than 1,800 mᵌ/h

- Centre distances greater than 90m

- Symmetrical weight distribution for longer service life of chain and drive shaft

- No mechanical connection between the bucket strands

- Material feed with flow divider

- Sprockets and tension shafts have separate bearings, so that if chain lengthening occurs the chains can be realigned individually

Bucket Elevator with Gravity Discharge type BWZ-S

For bulk materials which create a lot of dust and have particle sizes of up to 150 mm AUMUND offers a Bucket Elevator with Gravity Discharge type BWZ-S. This Bucket Elevator runs at reduced conveying speeds and uses gravity to discharge the bulk material over the back of the preceding bucket.

Functions and characteristics

- Conveying speeds when using gravity discharge are between 0.5 and 1.11 m/s

- Special bucket design – the bulk material flows over the back of the preceding bucket into the outlet

- Bucket widths from 200 to 1,200mm and protrusions of 240 or 400mm

- Conveying capacity of up to 680 m³/h

- Conveying capacity as Double Bucket Elevator of up to 1,350 m³/h

Products & Systems

Discharge Systems

Bucket Elevators

Chain Conveyors

Apron Feeders

SAMSON® Material Feeder (fixed)

Samson® Material Feeders (mobile)

Pan Conveyors

Telescopic Spouts

Circular Storage

Longitudinal Storage

Stackers, Reclaimers & Combined Machines

Wagon Unloading Systems & Wagon Tipplers

Eco Hoppers

Shiploader