Chain Conveyors

Armoured Plate Conveyors and Drag Chain Conveyors: environmentally friendly and cost-effective technology for cohesive and dusty bulk materials

Chain conveyors are generally used when cohesive bulk materials such as chalk, gypsum, clay or raw coal are to be discharged from a hopper. For such applications AUMUND offers the Armoured Plate Conveyor type PKF.

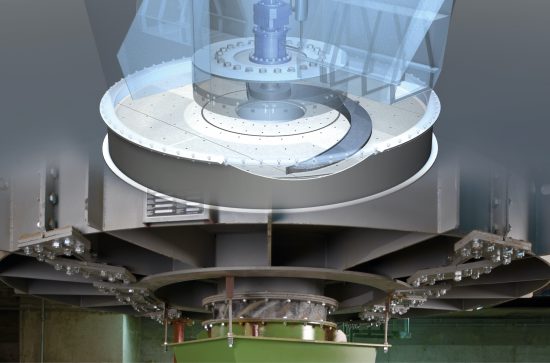

Where filter dust or additives have to be extracted, the AUMUND Drag Chain Conveyor type LOUISE TKF is often used. Because this machine conveys the bulk material in a closed trough, its operation is not damaging to the environment.

Applications

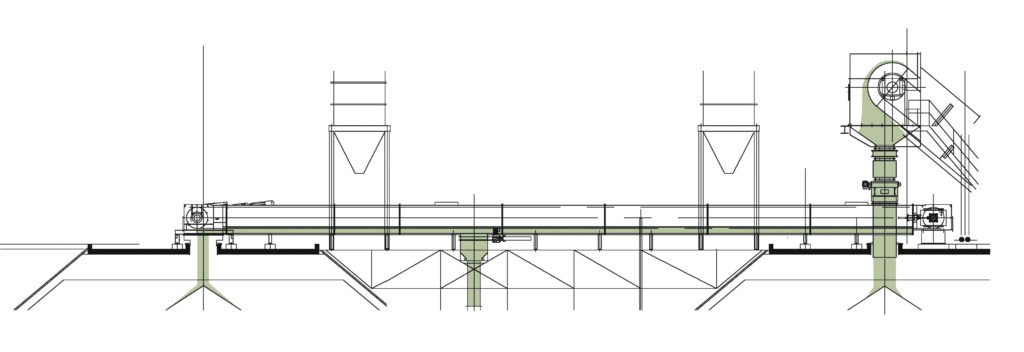

Distribution of various types of bulk materials

Controlled feeding of the Chain Conveyor is achieved with one single feeding chute. The number of discharge outlets will vary according to plant requirements. All intermediate discharge outlets are fitted with remote controlled shut-off gates allowing the central control room to select which silo will receive the material. The final discharge outlet in the drive station remains open at all times.

Reclaim of bulk material from various silos or hoppers

Either a double-row needle gate or a motorised slide gate, which remains open during normal operation, isolates the silo or hopper from the Chain Conveyor for maintenance purposes. During the discharge process the full load of the bulk material is supported by a discharge table located underneath the reclaim outlet on the return run.

This arrangement enables volumetric discharge at the required rate by regulating the height of the material layer, either by the chain speed with a frequency converter, or with a motorised or manual level control. Discharge onto subsequent equipment is realised through the discharge outlet in the tension station.

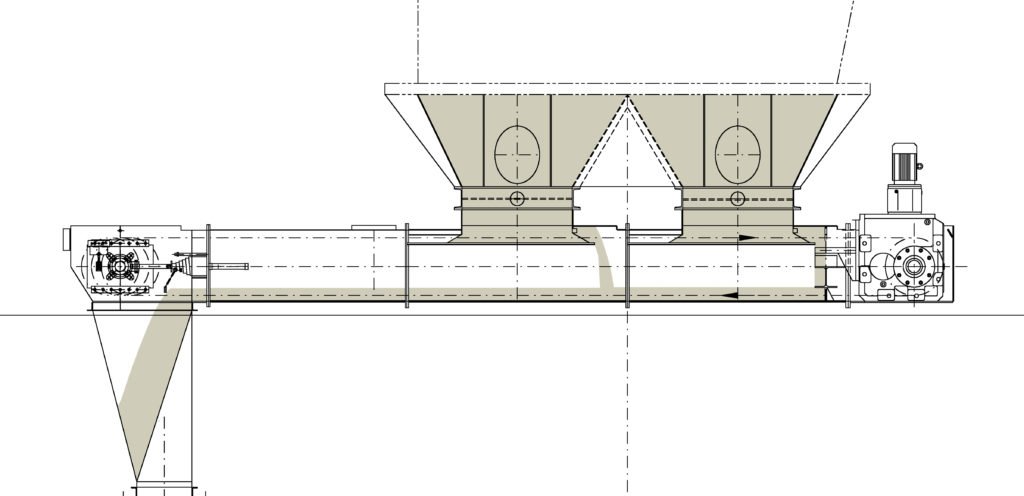

Coal Mill Feeding

For coal mill feeding applications all Chain Conveyors come in a shock-pressure proof design resistant up to 3.5 bar as a standard. These Chain Conveyors feature a double-strand chain. A variable speed drive with frequency converter ensures a uniform material flow and controlled feeding.

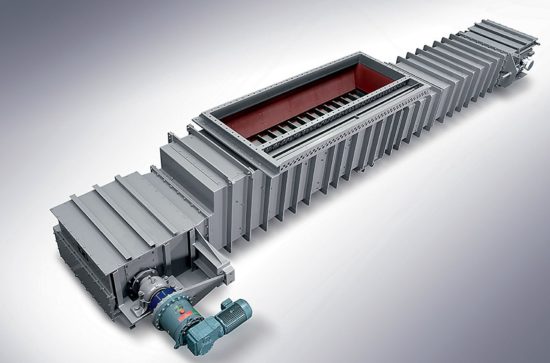

Armoured Plate Conveyor type PKF

The Armoured Plate Conveyor type PKF from AUMUND is used in the cement, lime and gypsum industry for hopper discharge of crushed limestone or for cohesive raw materials such as chalk, gypsum, marl, clay or raw coal.

Functions and characteristics

- Low construction height

- Round link chains and specially formed scrapers for cohesive materials

- Clean operation because hopper and conveyor form a closed unit

- 2 to 5 strand versions (dependent on application and surroundings)

- Discharge capacity of up to 1,800 mᵌ/h

- Construction widths between 600 and 2,600mm

- Chain strands for traction forces up to 690 kN

- Chain strands with breaking loads of up to 1,000 kN per strand

- Chain spacing of 400, 500 or 600mm

Drag Chain Conveyor type LOUISE TKF

The AUMUND Drag Chain Conveyor type LOUISE TKF has proved itself as a solution for environmentally friendly transportation of challenging bulk materials for many years all over the world. It is often used for mill feeding and filter dust handling.

Functions and characteristics

- Forged and surface hardened fork link chains

- Available in single or double chain design

- High tensile strength

- Reinforced sprockets (particularly in areas of high wear)

- Flights can be selected according to bulk material properties

- Horizontal, inclined or vertical conveying is possible

- Non-slip material transportation

- Dust-tight components also available in gas-tight, pressure-tight and water-tight design

Products & Systems

Discharge Systems

Bucket Elevators

Chain Conveyors

Apron Feeders

SAMSON® Material Feeder (fixed)

Samson® Material Feeders (mobile)

Pan Conveyors

Telescopic Spouts

Circular Storage

Longitudinal Storage

Stackers, Reclaimers & Combined Machines

Wagon Unloading Systems & Wagon Tipplers

Eco Hoppers

Shiploader