Metallurgy

Ideal Solutions and Products for Ferrous and Non-Ferrous Metallurgy

One key focus of the AUMUND Group is the multitude of applications of AUMUND Fördertechnik equipment in ferrous and non-ferrous metallurgy, as well as in coking plants and foundry technology. It has special expertise in conveying hot materials with temperatures up to 1,000°C using inert gas technology, and in the careful cooling of iron briquettes and similar delicate products.

SCHADE Lagertechnik also participates in the manufacture of iron, steel, aluminium and other metals, both on the raw materials side and in the handling of dry fossil fuels. Production of metals is extremely energy intensive, therefore it is important that the supply chain remains as intact as possible. Strategic material storage is the key to ensuring continuity in the process. This is the reason why SCHADE Storage Systems, Blending Beds and Wagon Unloading equipment for coal and coke are successful all over the world.

SAMSON Materials Handling stands out in ferrous and non-ferrous metallurgy as well as in foundry technology, with its mobile solutions for the loading and unloading of bulk materials with varying properties, from moist and sticky to dry and dusty. One example is cohesive, fine grained iron ore with a high moisture content, which can be transported reliably and without risk of bridging or blocking.

AUMUND Conveying and Cooling in the Iron and Steel Industry (PDF)

AUMUND Conveying and Storing in the Aluminium Industry (PDF)

AUMUND Fördertechnik supplies conveying and cooling systems for direct and smelting reduction processes as well as for the blast furnace route in ferrous metallurgy. These include applications for horizontal and vertical conveying of various bulk materials, for silo or hopper discharge as well as specialised solutions for particularly hot and abrasive bulk materials, sometimes under inert gas.

Applications and Process Stages for AUMUND Solutions and Equipment

Direct Reduction and Smelting Reduction

AUMUND has developed innovative conveyors to transport hot DRI (direct reduced iron, also known as sponge iron) from the Midrex shaft furnace process, rotating furnace process or fluidised bed process, for example to allow direct hot charging into an EAF (electric arc furnace). Several special applications have been developed for this technological environment. The hot material and cooling conveyors are the leading technology of this type in the world.

- Continuous direct feeding of DRI to EAF (hot charging)

- Potential energy savings and increased productivity

- Up to 900° Celsius

- Special conveyor with the AUMUND Inert System

- Proven sealing technology

Feeding DR

AUMUND Bucket Elevators operate with remarkably high conveying capacities to feed material to direct reduction plant.

Hot Discharge

AUMUND has developed innovative conveyors for transporting hot DRI (direct reduced iron) under inert gas.

Direct Charging of Electric Arc Furnace

Special AUMUND conveyors operate reliably all over the world as short or long-distance direct connections from direct reduction plant to electric arc furnaces. This pioneering application allows considerable energy savings and improvements in the productivity of the plant.

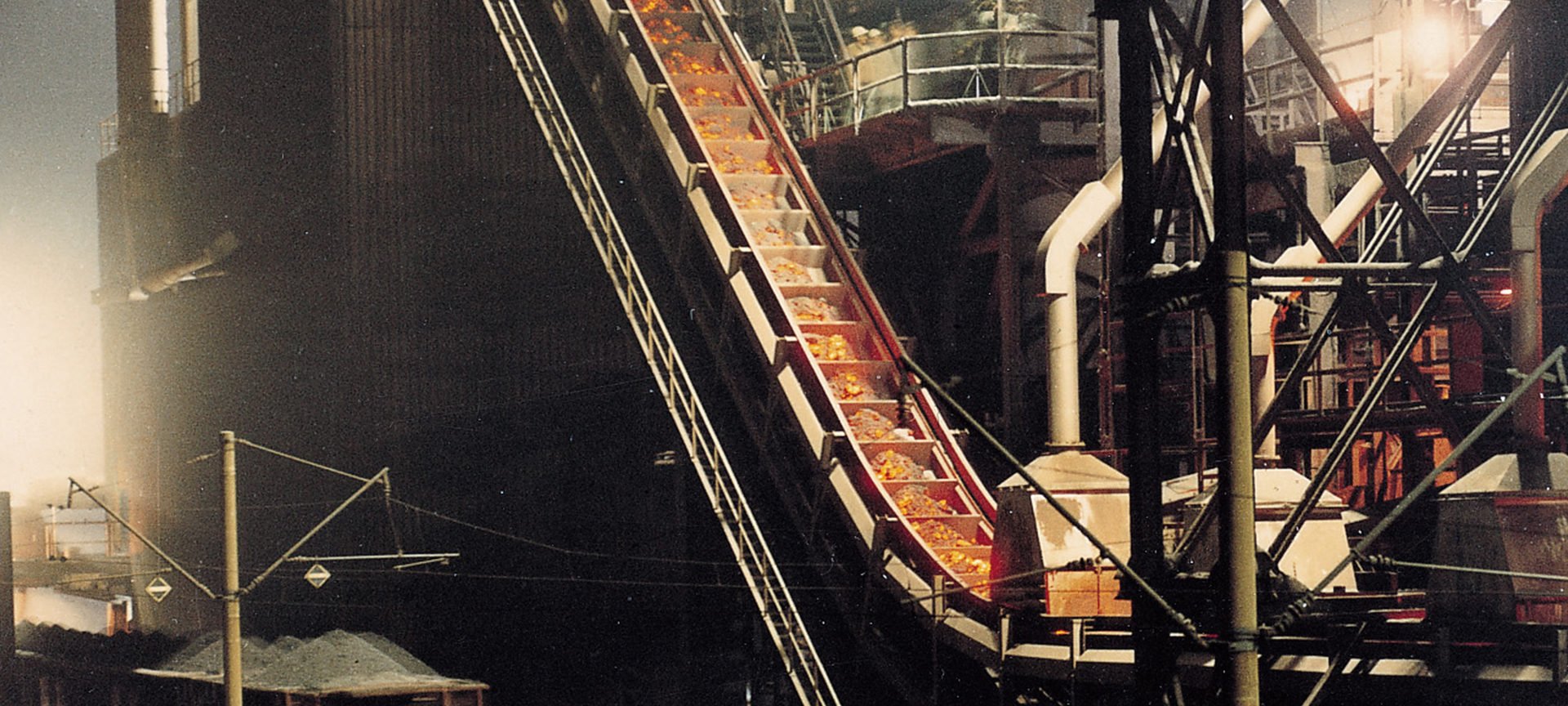

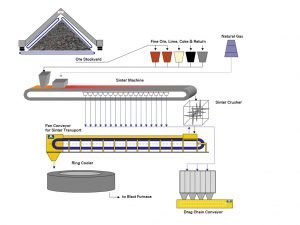

Sintering Plant

Transportation of hot sinter up to 1,000°C from the sintering plant to the cooler, or even after the cooler if the material at that point is still too hot to be transported by a standard belt conveyor.

Advantages and Characteristics of the AUMUND Sinter Conveyor

- Reduced energy requirements and lower noise levels create better working conditions than with vibrating feeders

- The avoidance of relative motion between the sinter and the conveyor reduces both wear and tear on the equipment and degradation of the sinter

- The exact overlapping design of the conveyor sections minimises spillage

- Low maintenance requirements

Modern sinter shaft coolers use part of the thermal energy from the hot sinter in their process, and are connected by insulated AUMUND Sinter Conveyors, to optimise energy recovery.

Coking Plant

AUMUND conveying equipment is used in coal treatment (in ATEX design) and to transport coke to the coking furnace or to the wet quenching process. AUMUND Rotary Discharge Machines type LOUISE BEW, and Rotary Plough Feeders type Besta&Meyer RFX, reliably clear the coke from the ramp after quenching. Alternatively, the coke can be transported while still hot by the AUMUND Hot Material Conveyor type KZB-H directly to the dry coke cooling process (KTK).

Dry Coke Cooling Process (KTK)

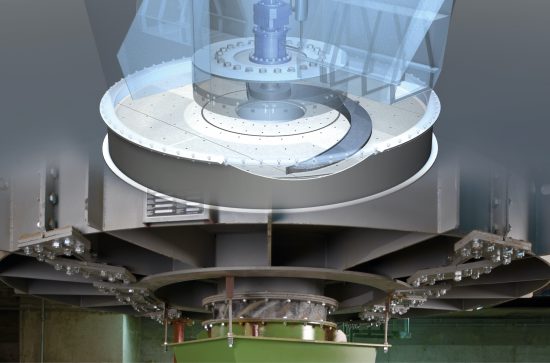

If the dry coke cooling process (KTK) is loaded directly, both the size of the buffer zone of the KTK, and therefore capital expenditure, can be reduced considerably because of the largely continuous conveying cycle. In addition, the operation of an AUMUND Discharge System type CENTREX® CTX allows a lower construction height.

Blast Furnace Charging

Charging of the blast furnace can be carried out under appropriate conditions by selected AUMUND conveying equipment. For example, compact blast furnaces can be introduced, or existing skip conveyors can be replaced as part of a modernisation project. The input materials can also be charged at high temperatures if necessary.

Scrap Transport

Automated conveying of particularly large or solid pieces of scrap such as crop ends, belt cones, belt bases, offcut scrap in pickling plants or hot end pieces in rolling mills, is feasible with AUMUND Pan Conveyors type KZB.

Filter Systems

Depending on the type and design of filter system, dust and dry filter debris is transported from the filter discharge to designated storage silos by AUMUND Drag Chain Conveyors type LOUISE TKF and AUMUND Bucket Elevators.

Additives

Additives or other input materials which are delivered for a variety of reasons by truck, can be received by the Samson® Material Feeder, which avoids complex, costly civil works and at the same time minimises dust.

Pelleting

In pelleting plants AUMUND conveying systems facilitate horizontal, vertical or inclined transportation of bulk materials. Further applications such as silo and hopper feeding are carried out all over the world by AUMUND Bucket Elevators and Drag Chain Conveyors, and silo discharge by CENTREX®.

Conveying of Hot Pellets

Pellets come out of the rotary kiln at temperatures up to 800°C and are transported to or from the cooler by AUMUND Pan Conveyors type KZB.

Pellet Cooling

If the cooling capacity of the main cooler is not sufficient, additional cooling by air of hot pellets can be carried out by an AUMUND Cooling Conveyor type KZB-K, which is specially adapted for air flow.

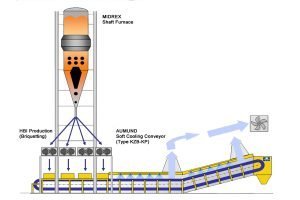

Briquetting Plant

Conveying and cooling of HBI iron ore briquettes (hot briquetted iron) underneath briquetting presses is a typical application for AUMUND Hot and Cooling Conveyors type KZB-H and KZB-K.

HBI Conveying

Transportation by AUMUND Hot Material Conveyor type KZB-H from the briquetting press to onward processing.

HBI Cooling

Controlled slow cooling (smooth cooling; no quenching tank) of the HBI on the patented AUMUND Cooling Conveyor type KZB-K with a mixture of air and mist for high quality briquettes:

- Controlled, slow cooling of the materials (no quenching tank)

- Achieves the desired characteristics

- Patented “Smooth Cooling” with a mixture of air and mist

Advantages and Characteristics of the AUMUND HBI Cooling Conveyor

- Cooling with the aid of a defined water mist with low water consumption

- Avoids creation of sludge

- Enclosed system results in a clean environment

- Improvement of HBI quality by slow cooling

Material Storage

AUMUND Rotary Discharge Machines type BEW are used to extract typical bulk materials from longitudinal storage or batteries of silos. Depending on the location and the application, various design types are available, for example block design, low profile design, low profile/radial, and circular. To avoid dust emissions, more and more covered storage is required. Silos can encompass considerably more storage capacity on the same surface area than can be achieved with longitudinal or circular storage piling.

AUMUND Rotary Discharge Machines are characterised by the following features:

- Installation under silos and covered longitudinal storage prevents dust emissions

- No dust monitoring, no risk of loss of material, no pollution by dust or groundwater contamination

- Maximum storage capacity on minimum surface area

- Materials from various silos or hoppers can be mixed

- The first in, first out principle prevents solidifying of material and protects from spontaneous combustion

Material Intake / Output

A variety of examples and solutions for shiploading can be found on the page of SAMSON Materials Handling, an AUMUND Group company. Longitudinal and circular storage equipment such as Stackers and Reclaimers as well as Wagon Unloading Systems from SCHADE Lagertechnik, also an AUMUND Group company, are to be found all over the world in the specialised area of material intake. AUMUND products often complete the package, for example in material discharge after wagon unloading.

In ferrous metallurgy a particular role is to be played in the handling of hot bulk materials such as sinter, pellets, DRI, HBI, fines, coal and coke. AUMUND products are used in conveying, feeding and discharge, as well as in cooling during conveying, if required, or if the transportation is to be carried out under inert gas, such as nitrogen.

AUMUND Conveying and Cooling in the Iron and Steel Industry (PDF)

Aluminium

In the aluminium industry AUMUND products are used in various areas, such as

- Delivery and conveying of aluminium

- Conveying and cooling conveying in primary and secondary smelters

Primary Aluminium

The AUMUND Cooling Conveyor type KZB-K is specifically installed in smelters which use the prebake process. The KZB-K offers particular advantages:

- Cooling of the materials in 6-8 hours to below 100°C

- Collection of the fluorine gasses produced during cooling

- Enhanced safety in the potline

- Better environmental conditions in the potline

- Improved automation

Secondary Aluminium

As the extraction of secondary aluminium is more attractive from an energy-use point of view than the manufacture of primary aluminium, this process is becoming more and more popular. Aluminium recycling contributes significantly to energy saving and at the same time to protecting the environment.

To equip a plant with AUMUND machinery, detailed planning and coordination is undertaken between the AUMUND engineers and the aluminium or recycling works. The most frequent applications are in conveying scrap for re-smelting, which can either be off-cuts of new aluminium from on-going production or used aluminium scrap.

Other Non-Ferrous Metals

AUMUND offers solutions oriented to specific applications for conveying and transporting typical bulk materials in metallurgical processes to produce non-ferrous metals such as copper, zinc and nickel.

AUMUND Conveying and Storing in the Aluminium Industry (PDF)

PRODUCTS & SYSTEMS

Flowsheet

Discharge Systems

Bucket Elevators

Chain Conveyors

Apron Feeders

SAMSON® Material Feeder (fixed)

Samson® Material Feeders (mobile)

Pan Conveyors

Telescopic Spouts

circular storage

Longitudinal storage

Stackers, Reclaimers & Combined Machines

Wagon Unloading Systems & Wagon Tipplers

Eco Hoppers

shiploader