Pan Conveyors

From Deep Drawn Pan Conveyor to Apron Weigh Feeder: secure transportation of hot, abrasive, moist and delicate bulk materials or those to be dosed

Automated production processes often require stockpiling or mixing of raw materials, additives or semi-finished products. Bottlenecks in feeding or discharging hoppers, storage, stockpiles or silos can adversely affect the performance of the plant.

The optimum design of the conveying and storage technology is the key, and AUMUND offers the appropriate Pan Conveyor for the application, adapted to the properties of the material to be conveyed.

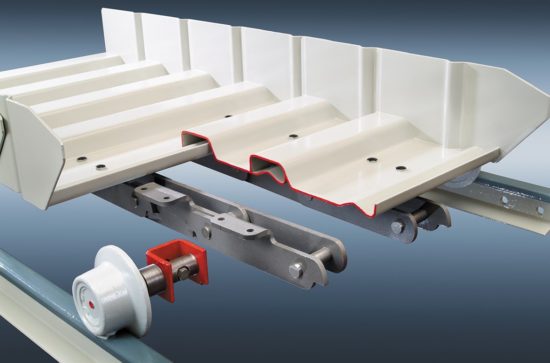

The AUMUND Pan Conveyor of the type KZB is a reliable and cost-effective piece of conveying equipment for hot and/or abrasive bulk materials.

Functions and characteristics

- Horizontal and inclined conveying up to 30° (material dependent)

- Plate widths from 400 to 2,400mm

- Conveying capacities up to 1,300 mᵌ/h

- Highly rigid AUMUND plate profile

- Reduced spillage because of overlapping plates

- Very quiet operation

- Low maintenance, long service life

- Various types available

- Available as Hot Material Conveyor and Cooling Conveyor

- With the addition of a weighing rail it can be used as a Dosing Conveyor (type DPB-K)

AUMUND Pan Conveyor type KZB

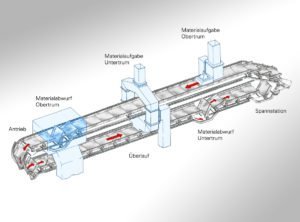

Special version: The Reversible Pan Conveyor

Specific plant layouts can require alternating conveying in two directions. In such cases the AUMUND Pan Conveyor of the type KZB-R, a special version of the Pan Conveyor is installed.

Functions and characteristics

- Horizontal design of the conveyor is recommended

- Managing from the control room ensures complete emptying of the conveyor sections before change of direction

- Large centre distances are possible with drive units at both deflection shafts

The AUMUND Bucket Apron Conveyor of the type BZB is the ideal solution for conveying at an angle of inclination up to 60°.

Functions and characteristics

- Small curve radius

- Suitable for heavy loads and high temperatures

- Buckets mounted close together for conveying of fine bulk materials

- Cross beams in the base of the buckets make them very stable

- The buckets can overlap forwards and backwards

- Standard bucket sizes up to 1,600mm wide

- Frequency controlled drive unit regulates the conveying volume

- Filling level monitor optional

AUMUND Bucket Apron Conveyor type BZB

Special version for operation in metallurgy: DRI / HBI Hot Material Conveyor BZB-I

Where the plant situation requires conveying of hot DRI or HBI, this can be carried out with the specially developed Bucket Apron Conveyor BZB-I.

Functions and characteristics

- Material temperature up to 1,100°C

- Horizontal conveying up to 300m (type KZB-I)

- Horizontal conveying capacity up to 1,300 mᵌ/h

- For inclined conveying the lifting height is dependent on the conveying capacity

- Inclined conveying capacity of up to 1,300 mᵌ/h (type KZB-I / BZB-I)

- Plate widths of the conveying sections from 400 to 2,400mm

- Plate widths of buckets from 400 to 1,600mm

- AUMUND Inert Gas System prevents re-oxidation and metallisation loss

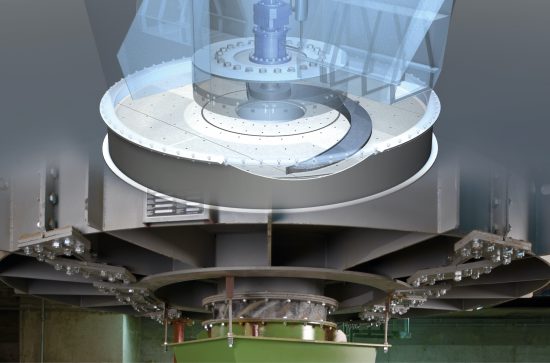

The AUMUND Flat Plate Conveyor type FPB is designed for gentle conveying of materials. A major application for this conveyor is in foundries where delicate castings or sand bales are transported.

Functions and characteristics

- Smooth, level surface for gentle conveying and transfer of material

- Effective reduction of noise and dust

- Overlapping, closed conveying sections to avoid spillage

- Energy efficient design

- Conveyor widths from 600 to 2,400mm

- Can be configured as a Weigh Conveyor

- Speed control by frequency converter

- Also available as Cooling Conveyor (with or without cover)

The AUMUND Pivoting Pan Conveyor of the type SPB is the perfect piece of conveying equipment for selective feeding of material if separate discharge into more than two silos or hoppers is required.

Functions and characteristics

- Remotely controlled interim unloading stations

- Different materials can be conveyed at the same time in the upper and lower runs

Depending on the material and the respective application, dosed feeding or discharge can be carried out by AUMUND Apron Weigh Feeders type DPB, either in the version with deep-drawn pans, type DPB-K, or in the version with arched plates, type DPB-B. The required gravimetric dosing at the desired degree of accuracy is achieved by an integrated measuring or weighing rail, the data from which drives the frequency converter, which in turn regulates the conveying speed and consequently the amount of material.

Functions and characteristics type DPB

- Volume controlled transportation of dusty or granular bulk materials such as clinker, granulated slag, petcoke or others

- Often used for cement mill feed

- Available in completely enclosed and pressurised design

Functions and characteristics type DPB-B

- Dosed extraction of bulk materials which do not flow easily, such as clay, gypsum, marl, limestone, pozzolana or others

- The bent plates are easy to clean with a scraper

Products & Systems

Discharge Systems

Bucket Elevators

Chain Conveyors

Apron Feeders

SAMSON® Material Feeder (fixed)

Samson® Material Feeders (mobile)

Pan Conveyors

Telescopic Spouts

Circular Storage

Longitudinal Storage

Stackers, Reclaimers & Combined Machines

Wagon Unloading Systems & Wagon Tipplers

Eco Hoppers

Shiploader