AUMUND NEWS 2//2022 – Products. Projects. Progress

AUMUND Fördertechnik

Smart conveying with PREMAS® 4.0

Order a Predictive Maintenance Solution, get one-year subscription for free

PREMAS® 4.0 is the Predictive Maintenance Solution from AUMUND that understands one of the biggest challenges in today’s industry: Running machines, maximum production, and regular maintenance are difficult to reconcile. For this reason, AUMUND has developed a maintenance solution based on smart technology. For customers, who want to benefit from optimised resources, increased machine reliability, and fewer unnecessary stoppages, AUMUND has a special offer available, valid until 30 April 2022: for every ordered PREMAS® 4.0 Predictive Maintenance Solution, you receive a one-year subscription free of charge.

PREMAS® 4.0 special offer

Move predictive maintenance for AUMUND and non-AUMUND conveying machines from theory to practice. Benefit from our special offer: Order a PREMAS® 4.0 Solution until 30 April 2022 and get a one-year subscription for free!

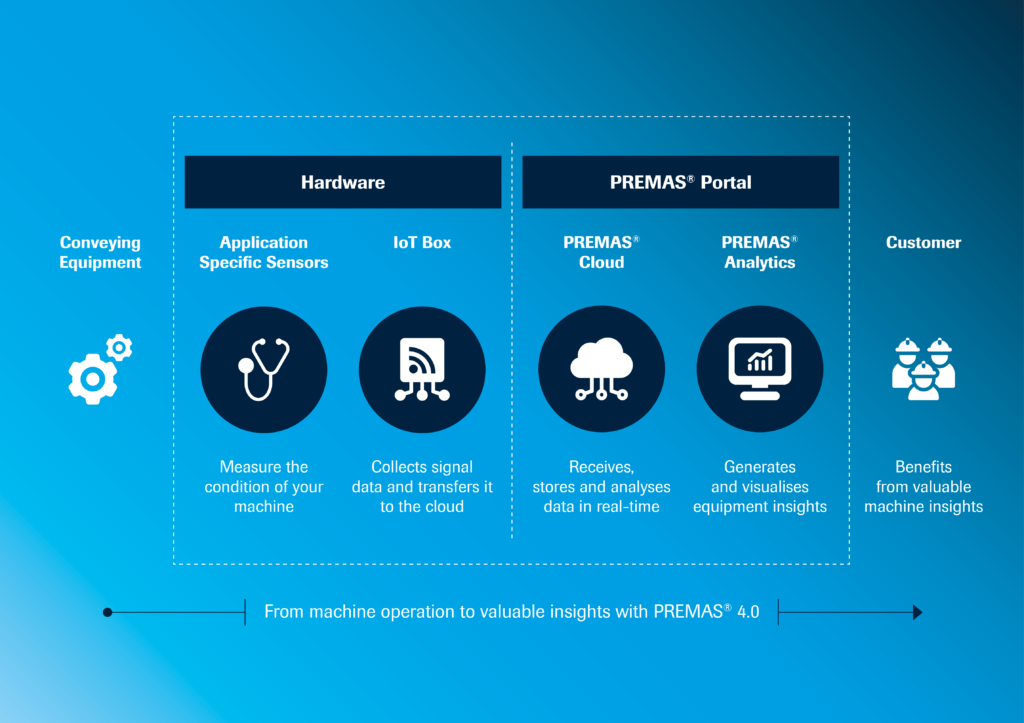

PREMAS® 4.0 breaks the Gordian knot between operation and maintenance

In every plant, there is this Gordian knot between operation and maintenance: most of the time, walk-by inspections are carried out, relying on the continuous measurements and sensors in the central control room. But many crucial observations cannot be made at a running machine, thus they remain under the water´s surface. PREMAS® 4.0 breaks this Gordian knot between operation and maintenance and helps to see, what you can´t see and detect, what you can´t measure. It is specifically designed for conveyors in the heavy industry and combines the latest sensor technologies with data collection and analysis to provide online information about the condition of your conveyors – in real-time and wherever you are, whenever you want to make the invisible visible.

Made visible at the touch of a button – anytime and anywhere

Every machine receives a hardware package consisting of sensors and an IoT Box. Provided field sensors and some existing signals from the plant control system are connected to the IoT Box, which sends the collected data to the PREMAS® Cloud via the cellular network. There, the data is evaluated based on the latest predictive analytics technologies. The PREMAS® Portal visualises and provides all relevant data for complete online condition monitoring, which is securely accessible to authorised users 24/7 and via any mobile or desktop device.

PREMAS® 4.0 Hardware – robust, IT / OT independent, and easy to install

The PREMAS® 4.0 Hardware is robust, IT / OT independent and fulfils all industrial requirements. It is currently CE, UL and EAC certified.

Specified on the type of conveying machine, you get your all-in-one kit such as:

• IoT Box

• Antenna Kit

• Temperature Kit

• Elongation Kit

• Further specific kits depending on your conveying machines

PREMAS® Portal – always one step ahead, 24 / 7 and on any device

The PREMAS® Portal is the secure gateway to all machine data, visualising the machine status in real-time, and presenting the results and calculations based on the collected data. It includes:

• Machine Overview: all machines with PREMAS® 4.0 at a glance

• Machine Dashboard: detailed overview of each machine and its KPIs

• Machine Performance: KPIs and detailed trend curves

• Anomaly detection: Push notifications in case of anomaly detection via E-Mail or SMS

• Predictive Analytics: Lifetime prediction of key machine components

• Traffic light principle: recognise immediately where you need to act next

• Interface to the central control room: possible on request

It is easy to say goodbye to unexpected downtimes with predictive maintenance

PREMAS® 4.0 comes in the form of a compact box and commissioning is as quick as it is easy: install the hardware, connect sensors and signals to it, log into the PREMAS® Portal, and then go back to production. The now connected smart solution feels the pulse of the machine, keeps an eye on it, and informs the user if there is a need for action. In the event of anomalies, PREMAS® 4.0 sends push notifications and provides a forecast of the expected service life of critical machine components.

You can thus plan your maintenance better, act in time, and prevent potential problems before operations are affected.

However, it is important to say: PREMAS® 4.0 does not replace an expert! The solution acts like your best friend, helping to prioritise maintenance, decide what to do next, and take action. But the decision-making power is yours!

Want to bring your maintenance and production to the next level?

Contact us and benefit from our special offer: Order a PREMAS® 4.0 Solution until 30 April 2022 and get a one-year subscription for free!

Contact

If we can help you with any further information, please use the contact form to get in touch.

You will receive an immediate automated acknowledgement, and we will respond to your enquiry as soon as possible.

Many thanks

AUMUND. SCHADE. SAMSON.