Smart conveying –

Prevent downtime with

PREMAS® 4.0 Predicitive

Maintenance Solution

Start › PREMAS® Maintenance Solutions › PREMAS® 4.0

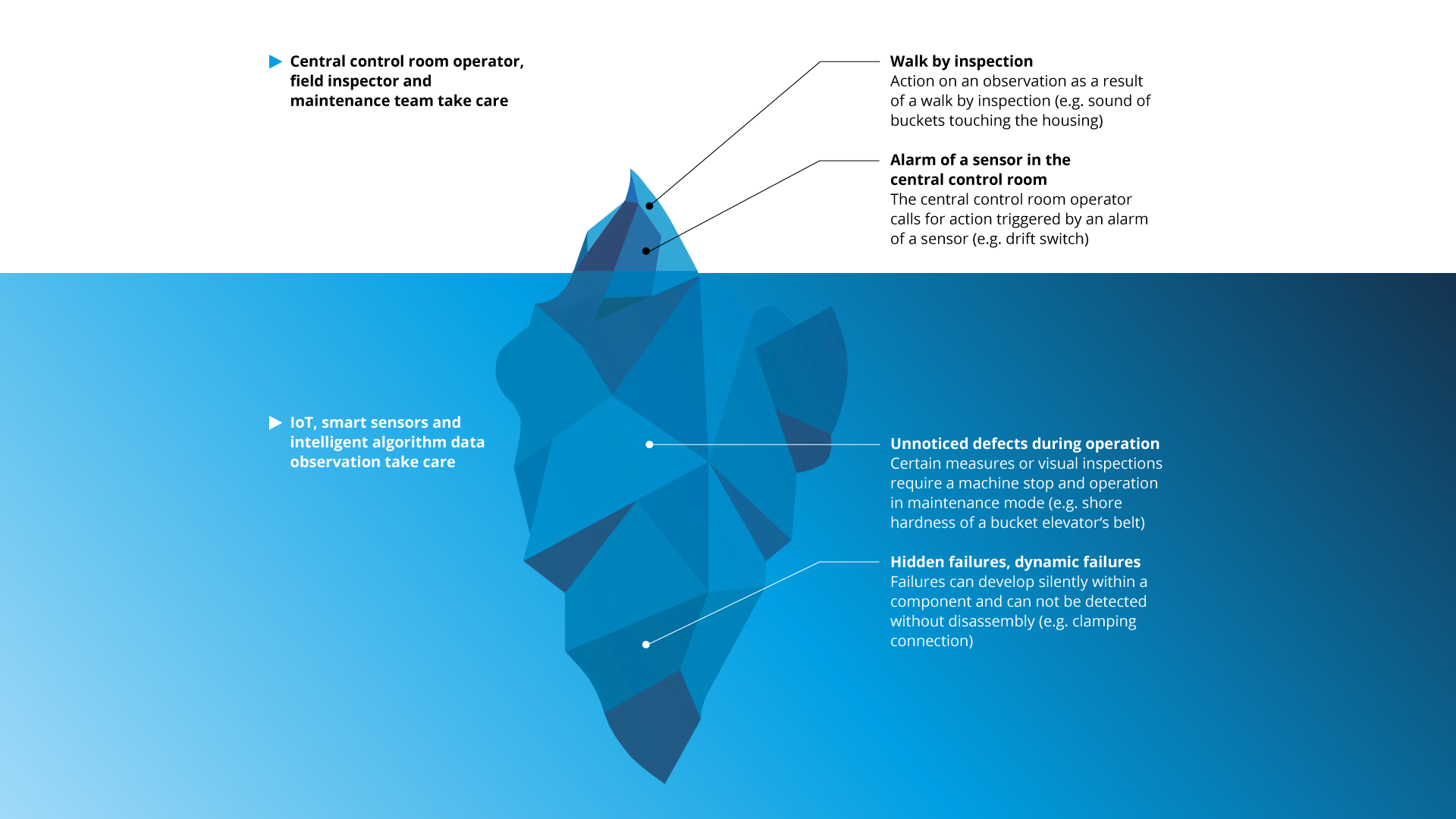

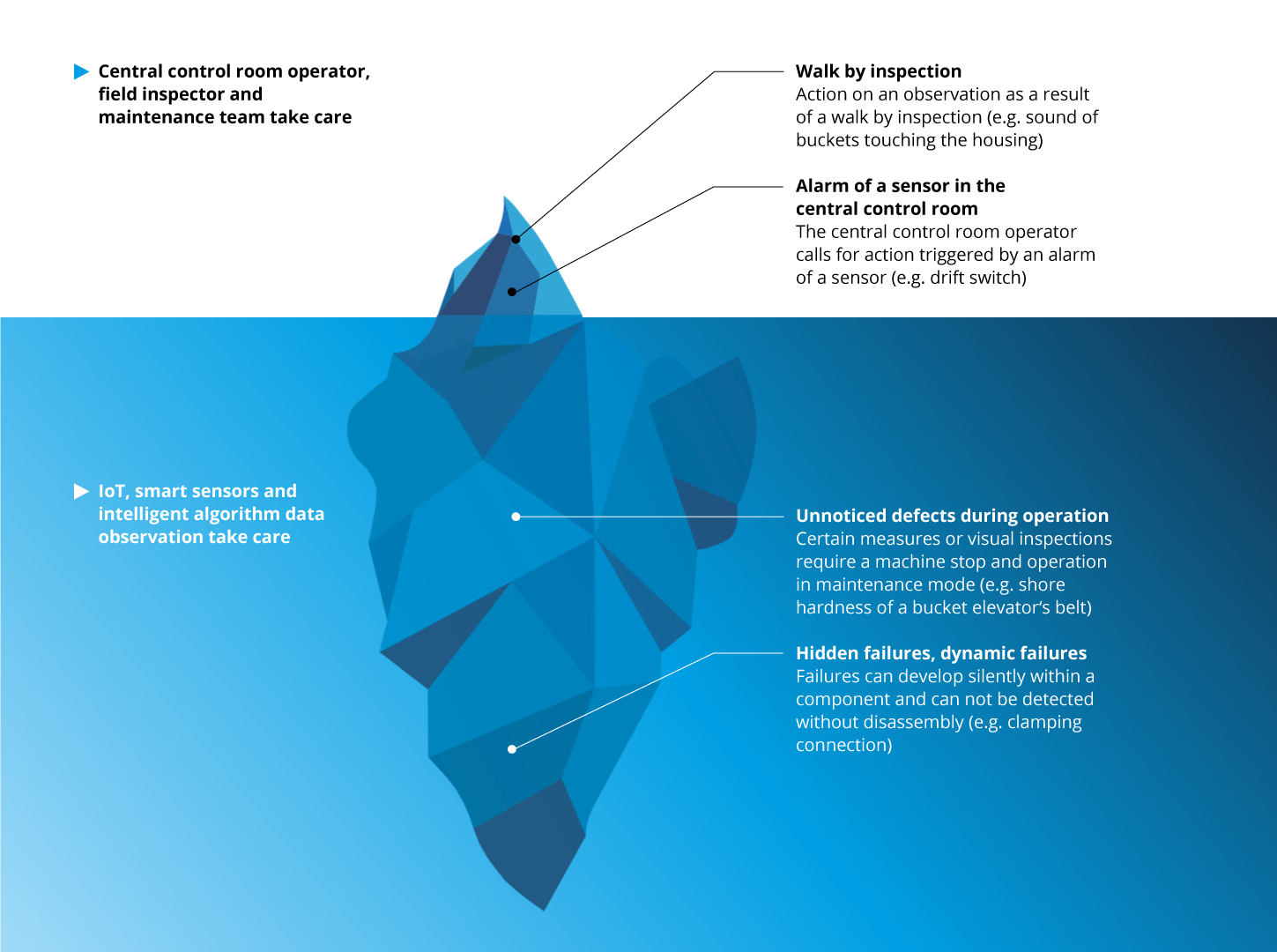

See what you can't see, detect what you can't measure – thanks to Predictive Maintenance

Regular maintenance activities and routines are therefore often a challenge: Machines cannot be maintained as required, inspections are postponed and the condition of components, their wear, or even damage, are not detected and remain under the water´s surface. This is a risk for the availability of the machine and the production rate of the plant.

Developed for AUMUND and non-AUMUND conveying machines, we have a solution that helps you plan regular maintenance activities, detect machine weaknesses at an early stage and act proactively to ensure your operation is not affected.

Made visible at the touch of a button – anytime and anywhere by PREMAS® 4.0

Our Predictive Maintenance Solution is specifically designed for conveyors in the heavy industry. The latest sensor technologies are combined with data collection and analysis to provide online information about the condition of your conveyors – wherever you are, whenever you want to make the invisible visible.

PREMAS® 4.0 comes in a compact box and commissioning is as quick as it is easy: Install the Hardware, e.g. IoT Box and application-specific sensors, connect the field sensors and required plant control signals to it, log into the PREMAS® Portal – and then go back to production.

PREMAS® 4.0 Hardware – robust, IT/OT independent, and easy to install

The PREMAS® 4.0 hardware fulfils industrial requirements and is currently CE, UL and EAC certified. Specified on the type of conveying machine, you get your all-in-one kit such as:

- IoT Box

- Antenna Kit

- Temperature Kit

- Elongation Kit

- further specific kits depending on your conveying machines

PREMAS® 4.0 Portal – always one step ahead, 24/7 and on any device

The PREMAS® Portal is your secure gateway to all your machine data: It visualises the status of your machine in real-time and presents the results and calculations based on the collected data. It includes:

-

Machine Overview: all machines with

PREMAS® 4.0 at a glance - Machine Dashboard: detailed overview of each machine and its KPIs

- Machine Performance: KPIs and detailed trend curves

- Anomaly detection: Push notifications in case of anomaly detection via E-Mail or SMS

- Predictive Analytics: Lifetime prediction of key machine components

- Traffic light principle: recognise immediately where you need to act next

- Interface to central control room: possible on request

Say goodbye to unexpected downtimes, unforeseen failures, and high OpEx / CapEx with PREMAS® 4.0 Predictive Maintenance Solution

PREMAS® 4.0 feels the pulse of your machine, keeps an eye on it, and informs you when action is required. It keeps you informed in real-time about the condition of your machine, sends push notifications in case of anomalies, and gives a forecast of the expected lifetime of critical machine components.

Thus, it enables you to plan your maintenance, act in time, and prevent possible problems before your operation is affected. However, it does not replace your experts! PREMAS® 4.0 is your best buddy enabling you to set priorities in maintenance, decide what to do next, and act!

Let´s bring your maintenance

and production to the next level!

Customer Statement of Ramona Keller

Maintenance Manager

Jura-Cement-Fabriken AG

Not sure yet?

Do you need more information?

Please find more details here:

PREMAS® 4.0 Questions & Answers

The solution can be applied to any belt or central chain bucket elevator as well pan conveyors (type KZB), CENTREX®, SAMSON Eco Hopper, SCHADE Reclaimers.

Installation of the temperature sensors and elongation sensor will take 4 to 8 hours of a mechanical fitter.

Pulling cable from sensor to IoT Box and mounting the IoT Box and antenna will take one / two days of an electrical team, depending on the local situation and cable ways. The IoT Box itself need to be wall mounted and starts automatically after power connection and does not need any local programming.

The payback depends heavily on the local labour cost, cost of manufacturing (cost of clinker and cement) and production rate. With PREMAS® 4.0 the regular stops for inspections can be reduced. Thus, savings are related to the time / cost of the inspector. The gains are related to the hours the conveying machine does not need a shutdown (e.g. 2 hours of additional clinker or cement production)

Example: With PREMAS® 4.0 possible failures of the clamping connection can be avoided. Savings are related to all costs a belt crash would cause (manpower, material, damages). The gains are related to the days the elevator needs to be rebuilt and production is stopped (e.g. 10 days loss of clinker or cement production). Similar costs can be avoided in case of a chain breakdown.