AUMUND NEWS 8//2019 – Products. Projects. Progress.

AUMUND Fördertechnik

Established in 1922 by his grandfather, Professor Heinrich Aumund, and carried on by his father, Günter Claus Aumund, the company has experienced a third generation since 1966, with Franz-W. Aumund being at the helm for over 30 years as Owner and President of the AUMUND Group of Companies, international leader in bulk materials conveying and storage technology. The AUMUND Group sets technological standards with its extremely reliable machines for conveying and storing bulk materials, in a multitude of key industries such as cement, limestone, gypsum, mining & minerals, iron & steel, chemicals, fertiliser, alternative fuels and ports and terminals, all over the world. Franz-W. Aumund explains in this interview what makes the Group successful, why he places so much emphasis on unity between the global members of the AUMUND Group, why he is strongly involved with social causes, and how he sees the future.

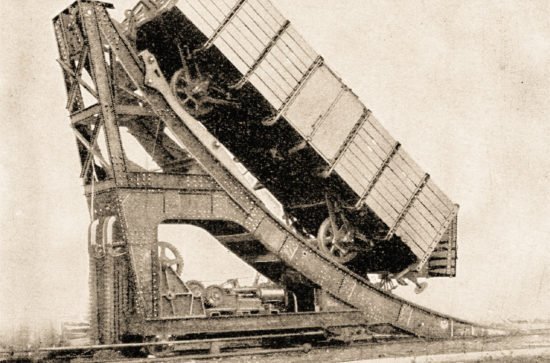

Mr Aumund, your name stands for a medium-sized group of companies enjoying international success over many decades, beginning with the supply of AUMUND steel pan conveyors to coal mines. With the development of a pan conveyor to travel a curved course, AUMUND set the first technological standard in this industry. This was followed by the wagon tippler and many other innovations, which to date have been the subject of over 200 patents. What in your view are the main factors which have upheld the position of the AUMUND Group as a global leader in conveying and storage technology over so many years?

Franz-W. Aumund: German specialised machinery manufacturing, benefitting from the “made in Germany” brand, (which is currently not showing itself in a good light in all branches of industry), from the point of view of the AUMUND Group is significantly characterised by three pillars: innovation, quality and reliability. For me this means that the top priorities are our continuous research and development work, the high quality of our machines and services, ongoing staff training and the aspiration to always be a reliable partner to our customers everywhere.

A further important factor is the financial strength which allows AUMUND to develop existing markets and also invest in new areas in order to establish ourselves in different industries.

The third pillar of success is our global presence and the distinct international focus of the Group. Today we are 19 companies, subsidiaries and branch offices, and five service centres across the world, with around 500 employees in Europe, Asia, India and North and South America, as well as a global network of over 80 agents. Success speaks for itself. The AUMUND reference lists document currently more than 22,000 machines in over 150 countries. With the volume of machine data growing at the same rate we are able to expand our experience every day and use it in new projects, and above all, in new international markets.

AUMUND is a household name in the cement industry. In which other sectors is AUMUND to be found?

Franz-W. Aumund: To answer this question we should take a quick look back at the roots. The activities of the company were influenced in the early 1920s by the German coal mining industry. It was at this time that the significance of and the requirement for robust and reliable steel pan conveyors, which were a technical innovation in underground applications, became clear. When at the beginning of the 1960s the mining crisis took hold, supply to the emerging cement industry increased under the management of my father, Günter Claus Aumund, in particular in Germany. The first products were pan conveyors and then came bucket elevators. Equally attractive was the requirement in the iron and steel industry for heavy steel pan conveyors, which had to withstand temperatures up to 1,100°C.

In short, pan conveyors and bucket elevators are real all-rounders. There is no bulk material, however hot, abrasive or chemically aggressive, that cannot be conveyed by an AUMUND Pan Conveyor or Bucket Elevator. The specific application dictates the technical design and dimensioning. Knowledge and alignment of these details are the key to opening up and penetrating further bulk materials markets of increasing importance to us, such as mining & minerals and the chemicals industry, in particular the fertiliser sector.

From a technological point of view, what particularly stands out about the AUMUND Companies today?

Franz-W. Aumund: In fact, today we have to look at the complete range of products and services of the AUMUND Group, from its three manufacturing brands, AUMUND Fördertechnik, SCHADE Lagertechnik and SAMSON Materials Handling. In a nutshell that means that our products and performance are always the connecting element between two stages of a process, whatever the industry. For example, we have been a partner to the cement industry all over the world since the 1970s, assisting with layout and design planning, where we are able to incorporate the product range of the Group, as it covers the complete production cycle of storage and conveying technology, from material extraction in the quarry or reception of material from ships or rail wagons, to bulk materials storage in circular, longitudinal or homogenising stockyards, through the complete production process up to loading of clinker. The particular advantage is that with all three product companies we offer an extremely broad spectrum with a very considerable intensity of product range. It is the same for all of the industries we supply.

Which current examples can you give us of measures to safeguard the future of the company?

Franz-W. Aumund: Innovation and investment are of the utmost importance to me. They secure the future of the individual companies, and with them the future of our Group. Targeted measures are always required to keep a house in order and then to extend it in future when the family gets bigger. We have an investment agenda which takes into consideration among other things markets, manufacturing locations, ideas and innovations as well as investment in employees. This is why we do not only concentrate on activities in our familiar key industries, but we also open up new future-orientated areas such as alternative fuels. Currently we are developing our own technology for processing replacement fuels from treated or pre-selected domestic refuse. This is a field which is becoming more and more important, both from an environmental and an energy efficiency point of view.

In order to sustain our extremely high level of commitment to the quality of our products into the future and on a global scale, and at the same time to future-proof our Rheinberg location, we run a comprehensive and multifaceted investment programme. For example, we are investing in our production facilities. Just recently a new robotic welding system and our new water jet belt preparation technology went into operation. Both of these systems will enhance precision and quality whilst reducing lead times, and optimising costs.

Not only belts but also our chains constitute the core components of our bucket elevators. With the acquisition of the experienced chain manufacturer TILEMANN in 2016 we took the first step to self-sufficiency in chains, and upgraded the facility with the latest CAD technology and presses. Now that this specialist manufacturer of high-quality chains and key components with its modern machinery belongs to the AUMUND Group, we are no longer dependent on outside suppliers. Product quality and product development are in our own hands, and we are firmly in control.

With an investment of around €200,000 the new show room, which has been established in a converted factory hall in Rheinberg, was another good decision for the future. Since July this year the display room has been delighting as a meeting point for customers as well as training and seminar participants.

Conservation has long been a serious matter for us. Way back in 2010 we installed a solar panel system on the roof of all 12 production halls in Rheinberg, which cost €2.2 million and provides 600,000 kilowatt hours of electricity per annum. In 2020 we will invest approximately €1.1 million in a state-of-the-art precipitation water drainage system in Rheinberg.

In recent years you have bought up other companies to add to the Group. What were the reasons for this?

Franz-W. Aumund: Looking back on the whole time period up to now, we can identify three strategic phases. The first phase went up to the end of the 1990s. During this period we invested predominantly in the development of our own products. Some of the significant product launches were the Pan Conveyor in 1962, the Bucket Elevator with Central Chain in 1968, Belt Bucket Elevator and Steel Silos in 1977, the Armoured Chain Conveyor in 1988, and in 2000 the first Arched Plate Conveyor.

At the beginning of the 1990s the second phase began. We started to expand our product portfolio by acquiring companies with an exact fit. My purpose in securing LOUISE Maschinenbau and WTW Engineering in 1991 and Besta & Meyer Maschinenfabrik in 2014 was first and foremost to concentrate the product know-how in drag chain conveyors and silo discharge systems, but also to strengthen our important spare parts business.

When we acquired 2001 SCHADE Lagertechnik, founded in 1879, and 2002 B&W Mechanical Handling, founded in 1966, (now SAMSON Materials Handling), we deliberately carried on the established brands in order to preserve their international name, their competence and their own identity, and of course to benefit from these advantages ourselves. The impact of the AUMUND Group on the market in this day and age is largely due to the three product companies, AUMUND, SCHADE and SAMSON. With their product ranges they are equally active in all key industries, often in conjunction with each other. The synergies between the companies, and their comprehensive conveying and storage solutions often lead to them being asked to give joint proposals for large projects.

We are currently in the third strategic phase, the era of our expanding international focus. Because the three product companies and the AUMUND subsidiaries are active internationally, the AUMUND Group now is spanning the globe. In 1975 the AUMUND subsidiaries in Brazil and Canada were incorporated, and in 1980 USA followed, with France in 1991, then Switzerland, in 1996 India and Hong Kong in 2005. The AUMUND representative office for technology, purchasing and production was opened in Beijing, China, in 1994 and this was followed by the incorporation of the AUMUND subsidiary in Beijing in 2006.

AUMUND is so well financed for the future that I am sure we will be able to remain in investment mode.

How do you see the position of the AUMUND Group in terms of service, which for you is an important aspect?

Franz-W. Aumund: A comprehensive service package is one of the paramount criteria for success in this competitive environment. AUMUND has massively increased its service spectrum in recent years, starting with an after sales function responsible for the classic spare parts business and for running maintenance seminars for plant managers and maintenance personnel, and culminating in the incorporation in 2017 of AUMUND Group Field Service GmbH, to secure a globally standardised commitment to quality in installation and commissioning of our own AUMUND, SCHADE and SAMSON machinery, as well as equipment of other manufacturers, with an internationally established network of about 60 supervisors.

Our innovative service concept PREMAS 4.0 is currently setting another emphasis. Its name reflects its programme, standing for “preventive” and in the style of Industry 4.0, our 4.0 stands for “Predictive Maintenance Service” meaning proactive, digitally supported maintenance instead of just precautionary maintenance. The hub for these activities is PREMAS AG in Switzerland, fully supported by our pool of inspectors and supervisors, and this is yet another important advantage within the AUMUND family.

In the AUMUND Group, people of approximately 30 nationalities are employed. How do you manage solidarity and the required efficiency?

Franz-W. Aumund: The knowledge and experience of our employees is for me the most important asset of the company, which is why we invest continually in education and training. In recruitment we build on qualified personnel from our own ranks as well as from outside. Our concept of lifelong learning starts off with opportunities for school pupils, and continues with our technical and commercial apprentices and students. What’s more, a new AUMUND Seminar Centre is currently being established in Leipzig, where courses on specially selected subjects will be held.

For staff development, in particular for managerial roles, we use our globally integrated network of AUMUND locations. In order to encourage international exchanges within the AUMUND Group, high achievers get many fixed-term transfer opportunities to gain valuable experience in other countries and get to know other cultures. In addition to the personal development of the employees I think it is also a good way to improve international team spirit and transfer of knowledge between sites, which is an extremely important basis for our internationally focused business.

As an example, Germany is of course the technological centre of AUMUND, but our colleagues in India support us in a very valuable way by developing for example also software programmes. As well as the sales activities of AUMUND India, we practically have our own software company there too.

The best pay-back that we get from our staff development is the strong loyalty of individuals to the company. Almost two thirds of our staff members have been with us for over five years, many for well over 15 years. Overseas postings at AUMUND subsidiaries such as Hong Kong and India or at SAMSON in England are also possible for participants in the scholarship programme that I initiated, together with Professor Detlev Borstell from Koblenz University of Applied Sciences, in 2009. To date we have sponsored almost 50 full-time mechanical and industrial engineering students, some of whom, as well as several dual work-study students, have since been taken on as employees.

We also work closely with the universities of Aachen, Bochum, Münster and Freiberg and with many other technical universities, taking advantage of their research activities in conveying technology. In addition we partner up with engineering firms and cooperate with other companies with similar strategies.

The charitable foundations you have established serve educational and also social purposes. Why do you have these issues at heart?

Franz-W. Aumund: In decades of travelling and having visited more than 100 countries, I have had some amazingly rewarding experiences, but at other times I have been left with a very negative impression. Based on the all of these encounters, I decided to take a global approach to supporting people and projects. With the mission statement “Training and education of young people is the most valuable investment in the future”, the Franz-W. Aumund-Stiftung and the companies of the AUMUND Group help for example children and young people from underprivileged backgrounds to find their place in society, by giving them a chance through education.

In 2018 the Aumund Foundation, AUMUND Fördertechnik and the AUMUND Group companies supported projects for education and social issues in Germany and abroad to the tune of more than €600,000. Alongside international projects in education and science the Aumund Foundation, which I established in 2018, also pursues initiatives in the medical field.

When you look back on a career spanning over 50 years at AUMUND, with more than 30 of those years in top management, what has had the biggest impact on you?

Franz-W. Aumund: Personally, from the very beginning, my contact with customers and the many different people all over the world is what has made its mark on me most strongly. One of my first trips took me to the cement industry in Brazil, where in 1975 I established the first AUMUND subsidiary. This was followed by USA, France, China, India, Hong Kong, Moscow, St. Petersburg, Dubai and now also Poland. I have been exposed to the most varied of cultures and characters, but one thing has always stayed with me: I do not have to embrace “different”, but I do need to respect it unconditionally.

In 2022 AUMUND will celebrate its 100th anniversary. What makes you sure that the AUMUND Group can look forward to a successful future?

Franz-W. Aumund: For over forty years the AUMUND Group has exported more than 80 percent of its production. For decades we have known for certain what globalisation means, where opportunities and risks lie, and what effects geopolitical influences can have. Therefore we are always vigilant, and try to recognise any changes in our sales markets, and political or economic uncertainties at an early stage, and take precautionary countermeasures.

A further prerequisite for success, now and in future, is that AUMUND Fördertechnik be led by a new and young management team. The Managing Directors, Dr Pietro de Michieli (Sales), Reiner Furthmann (Technology) and Dr Volker Brandenburg (Finance) have many years of international experience, which they have gained in leading positions with AUMUND and in other notable career postings. These are complemented by our experienced managers in the overseas subsidiaries who all have excellent knowledge of their markets.

I am convinced that we are well-positioned now and for the future and that we will always have the right ideas to enable us to recognise and fulfil the requirements of our customers.

Recently you celebrated your 75th birthday. What are your personal goals for the future?

Franz-W. Aumund: I will gradually step back from business operations, and adjust to a future consulting role in the Group. Principally I will concentrate more fully on the activities of my foundations. Currently I am also working on the extended new edition of the AUMUND company chronicles, “3 Generations – 3 Emphases”, which documents in detail the development of AUMUND during the eras of my grandfather and my father, both of which lasted for decades, and in my time the growing international focus of the company and the expansion of the AUMUND Group.

How do you feel about meeting up for another chat in 2022 when AUMUND turns 100?

Franz-W. Aumund: Absolutely, let’s do it!

Contact

If we can help you with any further information, please use the contact form to get in touch.

You will receive an immediate automated acknowledgement, and we will respond to your enquiry as soon as possible.

Many thanks

AUMUND. SCHADE. SAMSON.