AUMUND NEWS 6//2019 – Products. Projects. Progress.

AUMUND Fördertechnik

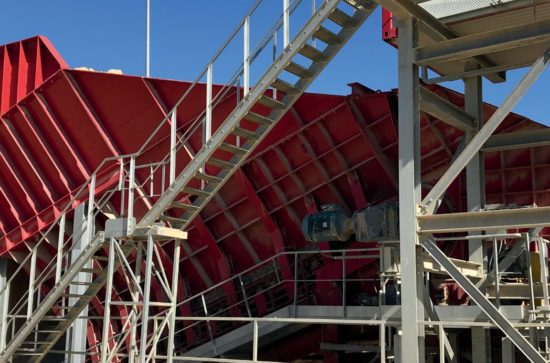

Crusher Feeding with AUMUND Arched Plate Conveyors.

In 2015 Cementownia Warta was the firstPolish company to make the decision to install an AUMUND Arched Plate Conveyor, for hopper discharge of clinker and sticky raw materials such as natural gypsum. Just one year later AUMUND supplied a further Arched Plate Conveyor to the Warta plant in Dzialoszyn to feed limestone to the crusher at a conveying capacity of 1,500 tph.

“We helped the customer on both projects from the beginning, providing support with the layouts and choice of the appropriate conveyors,” according to AUMUND sales engineer Peter Heberle and AUMUND project engineer Guido Mirbach. In 2017Budkrusz ordered a heavy-duty Arched Plate Conveyor type BPB-SF for the project at Transkom, also for limestone but with a capacity of 750 tph. The following year another heavy-duty AUMUND Arched Plate Conveyor was supplied to Poland, to Zaklady Wapiennicze Lhoist for its Tarnow Opolski plant, with a conveying capacity of 1,000 tph of limestone.

Facts

- The choice of a suitable discharge system relies heavily on the bulk material properties, the silo or hopper shape as well as the technical requirements of the process.

- In all three applications the AUMUND Arched Plate Conveyor stands out as a technically ideal and cost-effective piece of conveying equipment.

The AUMUND Arched Plate Conveyor is primarily used for sticky raw materials such as gypsum, anhydrite, clay and marl- clay mixtures. Its construction is of arched plates which overlap to create a rounded surface at the chain wheel in the discharge area. A cleaning scraper can be installed here in order to remove sticky materialfrom the plates. A drive unit combined with a frequency converter allows the speed of the conveyor to be regulated, to achievethe conveying capacity at a defined velocity.

Heavy-duty Arched Plate Conveyors of the type BPB-SF (mainly known as Apron Feeder with flat plates) are primarily arranged under tipping stations, and convey un-crushed raw materials, such as limestone and natural gypsum with dimensions of upto 1,500 mm, to the crushing plant. The thickness of the plates depends on the particle sizes of the material, the throughput and the dimensions of the hopper funnel.To accommodate these requirements, many plate thicknesses and widths of upto 3,000 mm are available. Accordingly the track chains have breaking loads of up to2 x 4,200 kN.

The BPB-SF design features heavy-duty, fixed, slide-bearing rollers, as used in crawler undercarriages, which are arranged underneath the track chains. In addition, AUMUND Arched Plate Conveyors are supplied with a spillage conveyor to remove fines without the need for manual cleaning.

“The choice of a suitable discharge system relies heavily on the bulk material properties, the silo or hopper shape as well as the technical requirements of the process”, explains Peter Heberle. In all three applications the AUMUND Arched Plate Conveyor stands out as a technically ideal and cost-effective piece of conveying equipment.

Contact

If we can help you with any further information, please use the contact form to get in touch.

You will receive an immediate automated acknowledgement, and we will respond to your enquiry as soon as possible.

Many thanks

AUMUND. SCHADE. SAMSON.