AUMUND NEWS 3/2023 – Products. Projects. Progress

AUMUND Fördertechnik

Predicitive Maintenance

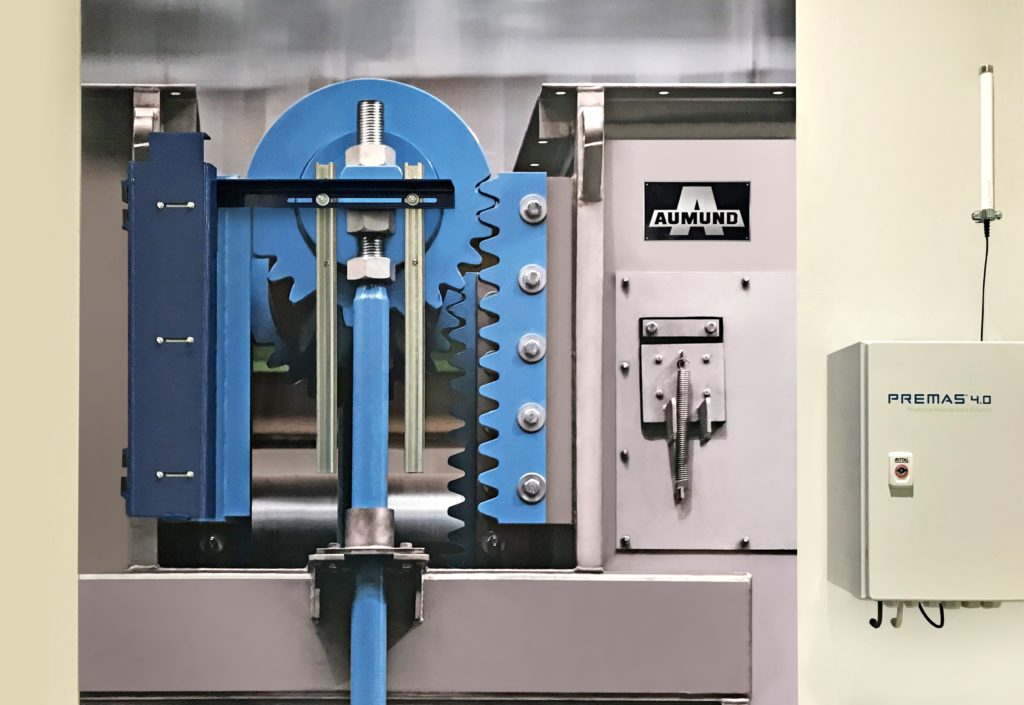

The PREMAS® 4.0 Predictive Maintenance Solution, an AUMUND digital service, has now been installed in more than a hundred applications

THIS IS THE STORY:

Since the digital service PREMAS® 4.0 Predictive Maintenance Solution was launched at the beginning of 2021 by the AUMUND Group, it has proved its value in practice in many installations all over the world. The online maintenance system, which was developed for the AUMUND Group with the technical participation of PREMAS AG, Switzerland has been brought to market over 100 times since inception.

Currently the majority of applications of the Predictive Maintenance Solution are on AUMUND machines such as Belt and Chain Bucket Elevators, Pan Conveyors and the Silo Discharge System CENTREX®. PREMAS® 4.0 is not only offered by AUMUND Fördertechnik and its international subsidiaries, but is also operated by customers of SCHADE Lagertechnik and SAMSON Materials Handling, companies of the AUMUND Group. SCHADE is known for such equipment as Reclaimers, Stackers and Wagon Tipplers, and the SAMSON range comprises mobile and stationary Material Feeders, and Shiploaders. Until now the focus was predominantly on operators in the cement industry, as shown by the list of internationally renowned reference customers. AUMUND is however convinced that the PREMAS® 4.0 System is actually of great interest to any industry which is constantly reliant on its bulk materials conveying equipment.

More than just data collection

The company states that the System combines the latest sensor technologies with data collection and analysis, enabling early recognition of wear and ageing of important machinery components of conveying equipment. It gives real time information 24 hours per day and 7 days per week about the condition of the machine and provides forecasts of the estimated remaining lifetime of critical components. It enables planning of maintenance and spare parts in advance, which in turn allows action to be taken in time to prevent potential problems.

In the market since 2004

Since the origins of PREMAS® in 2004, the AUMUND Group sees its purpose and objective as a comprehensive maintenance programme for all types of bulk materials handling equipment in the steel industry and in other key industries, and as the flagship of its customer service strategy. PREMAS® is short for Predictive Maintenance Solution. PREMAS® 4.0 was introduced at the beginning of 2021. This predictive online monitoring solution is at the same time also a component of the three PREMAS® 360° Maintenance Packages which have been in the market since July 2021. With the current version AUMUND is also planning the monitoring of clamping connections on Belt Bucket Elevators. Following tests carried out by development engineers, an on-site application of clamping connection monitoring has taken place in a cement plant in Poland.

Retrofitted installations

In 2022 AUMUND India installed PREMAS® 4.0 when it converted the tallest (175.3 m) Bucket Elevator in the world at the ACC Wadi Cement Plant (Holcim Group). Titan Cement in Greece is benefitting from the advantages of the digital System in the conversion of a Chain Bucket Elevator not originally manufactured by AUMUND. At the same time implementation of the maintenance System is also very interesting for customers all over the world when purchasing new equipment and when modifications are carried out on own-brand machines.

AUMUND editorial published in Stahl+Eisen 01/2023 in German language (translation by AUMUND Fördertechnik GmbH)

Contact

If we can help you with any further information, please use the contact form to get in touch.

You will receive an immediate automated acknowledgement, and we will respond to your enquiry as soon as possible.

Many thanks

AUMUND. SCHADE. SAMSON.