AUMUND NEWS 3//2020 – Products. Projects. Progress.

AUMUND Fördertechnik

AUMUND Conveying and Cooling Equipment for Foundries.

Reliable and cost-effective solutions

To keep pace with the rapid developments in casting technology today, new methods and innovative handling systems are required. Smooth handling is often a major factor in assuring the qualityof the castings, which is why it is important to select the right conveyor for the application.

AUMUND conveying and cooling equipment has a well-established reputation in high performance applications, and offers reliable and cost-effective solutions for foundries.

The AUMUND product range covers

Conveyors for degating, sorting and cleaning

Cooling Conveyors

Bucket Elevators

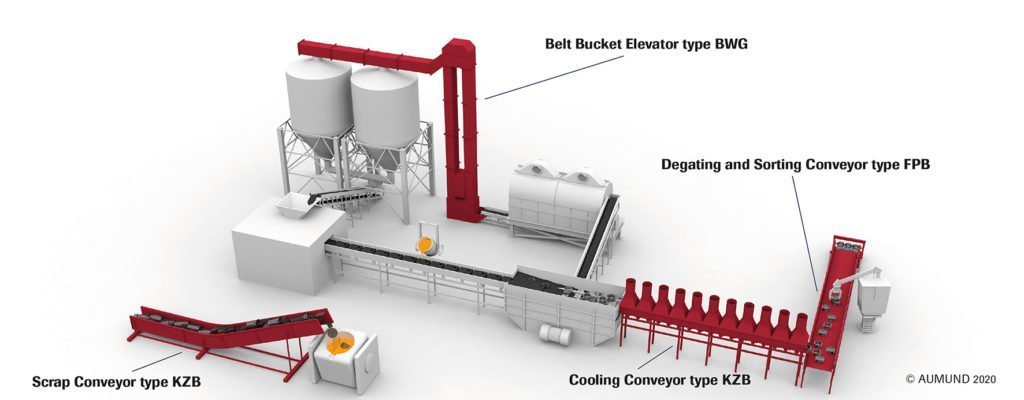

AUMUND Equipment for Conveying and Cooling in Foundries

Applications

AUMUND Conveyors for degating, sorting and cleaning

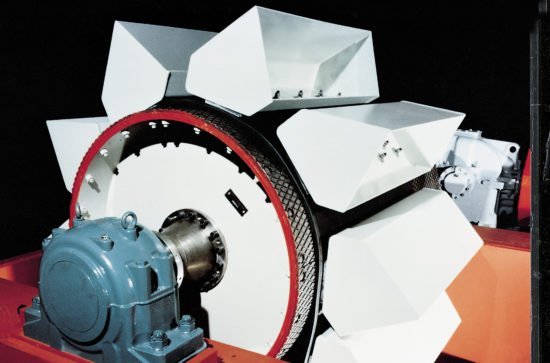

- Mechanically and statically sound conveyors of the proven construction types FPB and KZB

- With high resistance to the impact loads coming from the degating tools such as manual hammers, hydraulic wedges and even manipulators

- Compact footprint for installations withspace constraints

- Horizontal, slightly inclined or a combination of both, to fit into existing surroundings

Flat Plate Conveyor type FPB

- Plate widths from 600 to 2,400 mm

- Level, horizontal surface for smoothconveying and material feed

- Tightly overlapping conveying sections• Modern frequency controlled drive units

- Automation to suit moulding cycle times

Pan Conveyor type KZB

- Pan widths from 400 to 2,400 mm

- Profiled pans for ascending ordescending transport

- Sturdy components resistant totemperatures of up to 1,000°C

- Patented pan overlapping system• Low power consumption

AUMUND Cooling Conveyors

AUMUND uses proprietary technology to calculate and guarantee the appropriate controlled “smooth cooling” of thecastings from shakeout to degating or shot blasting. The main component of this technology is air under negative pressure in a cooling tunnel, where the castings are cooled to below 100 degrees, ready to be shot blasted, degated or sorted.

An added advantage of the casting cooler working in negative pressure is the lackof dust emissions into the foundry. The air flow and temperature are constantly monitored and automatically adapted to the type of casting and the output rate from the moulding line. The specialised conveyors can handle a whole day’s production of the foundry in a collective cooling operation. Defined cooling of the castings can be achieved by a mixture of air and water mist.

Each cooling conveyor is designed forthe individual application and the cooling connections can be supplied as an option.

AUMUND Bucket Elevators

Bucket Elevators for vertical conveying, available with central chain or steel- reinforced belt are well suited for abrasive bulk materials like foundry sand.

Bucket Elevator with Central Chain type BWZ

- Bucket widths rangingfrom 210 mm to 1,200 mm

- Conveying capacitiesexceeding 1,100 m³/h• Lifting heights up to 90 m

Belt Bucket Elevator type BWG

- Bucket widths rangingfrom 250 mm to 1,600 mm

- Conveying capacitiesexceeding 2,300 m³/h

- Lifting heights up to 175 m and more

Contact

If we can help you with any further information, please use the contact form to get in touch.

You will receive an immediate automated acknowledgement, and we will respond to your enquiry as soon as possible.

Many thanks

AUMUND. SCHADE. SAMSON.