AUMUND NEWS 2//2021 – Products. Projects. Progress.

AUMUND Fördertechnik

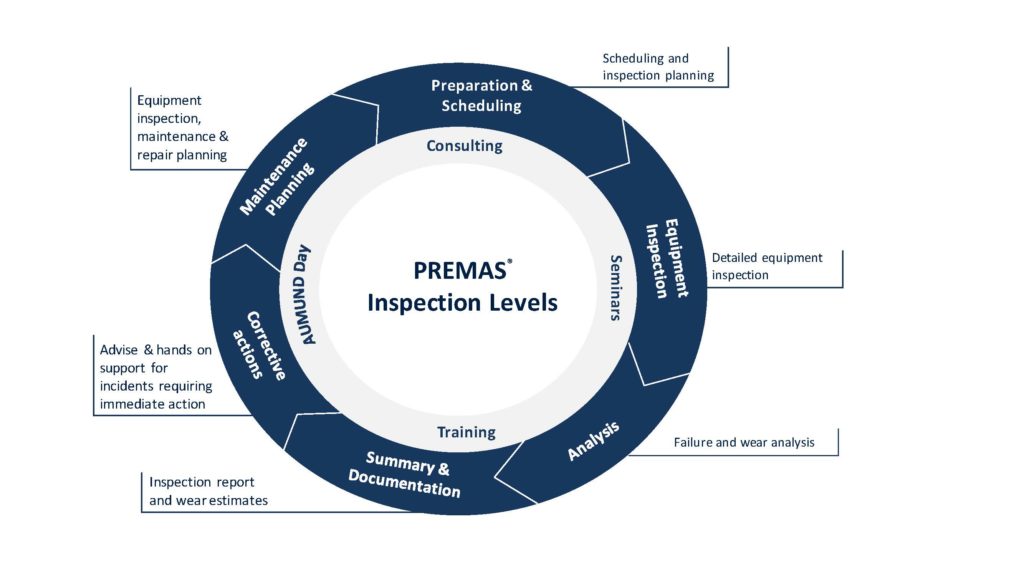

PREMAS® – Preventive Maintenance Service

PREMAS® is the brand name for AUMUND’s After Sales strategy including inspections, technical trainings, consulting, and PREMAS® 4.0 predictive maintenance. PREMAS® preventive inspections always have the task of helping to maintain the efficiency and therefore cost-effectiveness of machinery and equipment over long periods, and often result in enhanced performance.Unnecessary downtimes are minimised or even eliminated. PREMAS® inspections contribute to increasing servicelifetimes of machines and components, give early indications of requirements for spare parts, and make recommendations forpossible conversions. Only if conversion is not a viable option new equipment might be recommended. As a result of on-site inspections of AUMUND, SCHADE, SAMSON and other manufacturers’ equipment, customers are expertly informed and advised on questions of maintenance, spare parts supply, process optimisation and conversions.

PREMAS®

- Inspection

- Consulting

- Training

- increasing customer satisfaction

Vision and Mission

Reactive or insufficient maintenance often leads to unplanned stops, high costsand reduced production. Planned and predictive maintenance leads to proactive avoidance of shutdowns. A predictive maintenance strategy keeps machines at a high level of productivity.

Task and Objective

is to become the preferred provider of preventive maintenance services for all kinds of bulk materials handling machinery, providing inspections, training, spare parts and consulting to the cement industry, power plants, iron and steel and many other key industries.

Inspection reports provide a basis upon which customers can order spare parts, upgrades or machine conversions. By extension, if PREMAS® is a preferred inspection provider industry-wide, AUMUND will become the supplier of spare parts, such as chains and belts,on third party machines.

Preparation & Scheduling of the inspection

- Plant history

- Installation

- Maintenance and repairs

- Spare parts• Conversions

- Previous inspections or site work

Equipment Inspection

Detailed machine inspection

- Continuous data monitoring

- Vibration monitoring

- Alignment

- Visual inspection

- Wear measurement

- Shore hardness of belts

- Functional tests

Analysis

Fault and wear analysis based on:

- Functional tests

- Visual inspection

- Wear measurement

- Vibrations

Summary & Documentation

Inspection report and wear predictions

- Reliability

- Approximate running time

- Wear measurement

- Photos

- Maintenance and repair suggestions

- Inspection report

Corrective Actions

Recommendations for immediate requirements

- Repairs

- Adjustments

- Alignment

Maintenance Planning

Equipment inspection, maintenance and repair planning

- Greasing intervals

- Inspection plan

- Anticipated time frame for repair work:

- immediately

- within 3, 6 or 12 months

- Proposal for spare and wear parts

- Event log with machine history and data points

Consulting

Plant audit

- Increased production

- Reliability

- Remaining service life

- Repair

- Modernisation

- Modification

- New machine

Technical Training & AUMUND Days

Training of plant and operation managers as well as repair/maintenance personnel

- Failure detection

- Issues requiring attention

- Maintenance and repair instructions

- On-the-job training

- Operating instructions

Inspector Certification and Training Programme

Contact

If we can help you with any further information, please use the contact form to get in touch.

You will receive an immediate automated acknowledgement, and we will respond to your enquiry as soon as possible.

Many thanks

AUMUND. SCHADE. SAMSON.