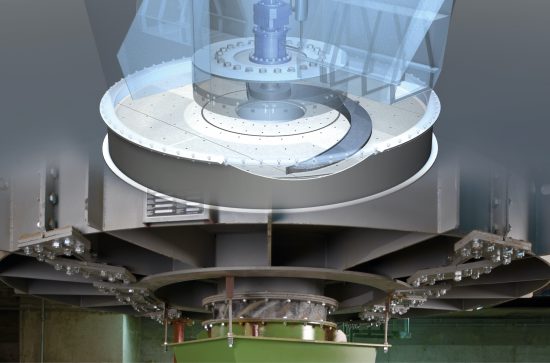

Push Chain Bucket Elevator

The next generation of bulk material conveying

The Push Chain Bucket Elevator is a patented vertical conveyor for controlled transportation of bulk materials. Its low space requirement and high equipment flexibility are important criteria for its implementation in many branches of industry, such as cement, fertilizer, ports and terminals (for loading and unloading ships), offshore loading stations, mining, minerals and metallurgy.

Supported by the DBU (German Federal Environmental Association) this vertical conveyor is also a sustainable alternative compared with other Bucket Elevators. The design of the Push Chain Bucket Elevator presents many advantages for plant operators:

Feature

- Drive unit at floor level

- Bucket strand is pushed, not pulled

- No drive shaft at the Bucket Elevator head

- No tensioning device

- Safe bucket emptying without centrifugal force for material discharge

- Discharge performance can be adjusted by a control disc

- Lateral material intake and discharge

Benefit

- Low centre of gravity

- Simple assembly and maintenance

- Safe and smooth conveyor operation

- No mechanical parts difficult to access at a great height

- Central discharge without interfering edges

- Fewer mechanical parts

- Speed adjustment depending on required capacity

- Meets the requirements of different material characteristics

- Flexible material intake and discharge directions

- Mobile applications possible

- Low height of inlet flange

new – patented – unique

To summarise, the Push Chain Bucket Elevator is a convincing new development for protective conveying of bulk materials, with features such as:

- Stable, reliable design

- Low risk of damage to material – suitable for materials which are abrasive and difficult to transport

- Energy savings of approx. 15 % because it uses the kinetic energy of the material conveyed

- Low maintenance and resource requirements – easily accessible drive components

- Suitability and flexibility for different bulk densities and particle sizes of materials

- Independence of emptying speed – suitable for conveying capacity peaks

- Can be used for fluctuating conveying quantities

- Flexible arrangement of the discharge chute – seamless integration into any plant process

The deliberate concept of flexibility of the machine in terms of conveyed materials and their characteristics, material feed and discharge positions, and operating modes, are the guarantees of maximum flexibility in equipment design and/or plant conversion.

The Push Chain Bucket Elevator has successfully completed its rigorous functionality testing, and has the following technical parameters:

- Lifting height up to approx. 200 m

- Bucket width up to 1,500 mm

- Conveying capacity of 2,000 tph

- Bucket filling rate around 90 %

- Speed of material discharge from 0.1 to 1.8 m/s

Products & Systems

Discharge Systems

Bucket Elevators

Chain Conveyors

Apron Feeders

SAMSON® Material Feeder (fixed)

Samson® Material Feeders (mobile)

Pan Conveyors

Telescopic Spouts

Circular Storage

Longitudinal Storage

Stackers, Reclaimers & Combined Machines

Wagon Unloading Systems & Wagon Tipplers

Eco Hoppers

Shiploader

STORMAJOR®