Longitudinal Storage

Systems for stockpiling, removal and reclaiming, covered storage systems and blending beds for homogenisation of raw materials

Longitudinal stockpiles are very often created where there is a necessity to store large volumes of bulk materials in between individual stages of a process. In addition, such buffer facilities are used for the homogenisation or mixing of different products. SCHADE Lagertechnik offers ideal solutions for both scenarios, incorporating:

- Stacking and reclaiming capacities from 100 tph to over 5,000 tph

- Covered storage systems for volumes up to 800,000 t or 1,000,000 mᵌ

- Stockpiles wider than 65 m

- Multi-purpose machines for multi-chamber stockpiles

- Reclaiming from multi-chamber storage buildings

- Fully automated operation (PLC)

Stockpiles are the simplest form of bulk materials storage. They serve as inventory or buffer storage and are an important link between material provision and production. Where it is necessary to protect from weather conditions or where environmental concerns make it a requirement, stockpiles are also constituted inside buildings. For both scenarios a range of typical stockyard arrangements have become established.

Outdoor Storage with Portal Reclaimer

- Stockpiling with Mobile Belt Stacker which has a boom which can be raised and lowered (it can also be slewed as an optional extra)

- Reclaiming with Portal Reclaimer (from stockpiles wider than 30m)

- Removal from the whole length of the pile or from pre-selected sections

- Fully automated operation

- Simultaneous stacking and reclaiming (of more than one stockpile)

- Rapid changing between stockpile sections

Outdoor Storage with Combined Portal Reclaimer

- Applications where simultaneous stacking and reclaiming is not necessary

- Stacking and reclaiming with only one machine (lower capital investment)

- Small footprint

Covered Storage with Portal Reclaimer

- Stockpiling with Mobile Tripper Car mounted under the roof of the building

- Pile cones can be stacked and reclaimed freely or partitioned by dividing walls

- Reclaiming with Portal Reclaimer

- Removal from the whole length of the pile or from pre-selected sections

- Fully automated operation

- Rapid changing between chambers or stockpile sections

- Portal Reclaimer design with two booms reduces the required height of the building

In many industrial processes a homogenous mixture of the raw materials is an important factor. This function of mixing or consolidation can be carried out on stockyards with blending bed technology. The best possible mixing effect is achieved by reclaiming from the front end of the pile with a Bridge-Type Reclaimer, if the Stacker has built up the pile so that its cross section has as many layers as possible of the same material. Just like inventory storage, blending bed technology can also be installed in storage buildings.

Outdoor Storage with Bridge-Type Reclaimer

- Stockpiling using the chevron method with a mobile belt stacker which has a boom which can be raised and lowered

- Reclaiming from the front end of the pile with a Bridge-Type Reclaimer

- Optimised homogenisation and final grain size of the bulk material

- Fully automated operation

- Simultaneous stacking and reclaiming (of more than one stockpile)

Covered Storage with Bridge-Type Reclaimer

- Stockpiling using the chevron method with a Mobile Tripper Car which is usually mounted underneath the roof of the building

- Reclaiming from the front end of the pile with a Bridge-Type Reclaimer

- Optimised homogenisation and final grain size of the bulk material

- Fully automated operation

- Simultaneous stacking and reclaiming (of more than one stockpile)

Bridge-Type Reclaimer

- Reclaiming the pile from the front end for maximum mixing effect combined with the appropriate stacking method.

- Discharge of material onto a reclaim conveyor via concrete ramp (parallel to the Blending Bed) or via inclined trough

- Drag trough as a solid component of the Reclaimer Bridge on the discharge end of the scraper chain

- Efficient homogenisation of the bulk material

- Rail spans up to 60m

- High conveying and homogenisation capacities (coal up to 2,200 tph)

Products & Systems

Discharge Systems

Bucket Elevators

Chain Conveyors

Apron Feeders

SAMSON® Material Feeder (fixed)

Samson® Material Feeders (mobile)

Pan Conveyors

Telescopic Spouts

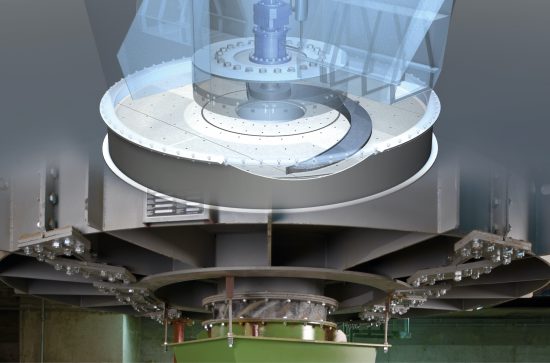

Circular Storage

Longitudinal Storage

Stackers, Reclaimers & Combined Machines

Wagon Unloading Systems & Wagon Tipplers

Eco Hoppers

Shiploader

STORMAJOR®