SAMSON NEWS 6//2019 – Products. Projects. Progress.

SAMSON Materials Handling

Waste Water Treatment Works.

How the Samson® Feeder deals with a sticky problem.

SAMSON has provided sturdy and long-lasting equipment to the waste water industry in the United Kingdom for more than 25 years. Samson® Feeders have been supplied across the country for use by companies including Yorkshire Water, Seven Trent Water Authority, Thames Water, Anglian Water, Southern Water, United Utilities and Degremont.

The Samson® Feeder provides an ideal reception unit for sticky materials due to the wide apron belt design and flexible side seals. This tried and tested design provides the strength of a chain feeder with the cleanliness of a belt conveyor. Surface installation of the Samson® Feeder not only eliminates the cost and time implications of underground pits and civil works but also allows for easier maintenance access and the flexibility to adapt the equipment to potential changes tothe site.

At waste water treatment plants the Samson® Feeder can be used for various functions. Typically the feeder acts as a truck reception unit to receive sludge cake for processing. Sludge cake can also be used as a fuel and the feeder provides an interface to supply the power plant. In some treatment plants the Samson® Feeder provides a useful horizontal storage area. Full dust and odour control measures are incorporated into the Samson® Feeder to suit the particular application.

SAMSON Material Feeders (all photos SAMSON)

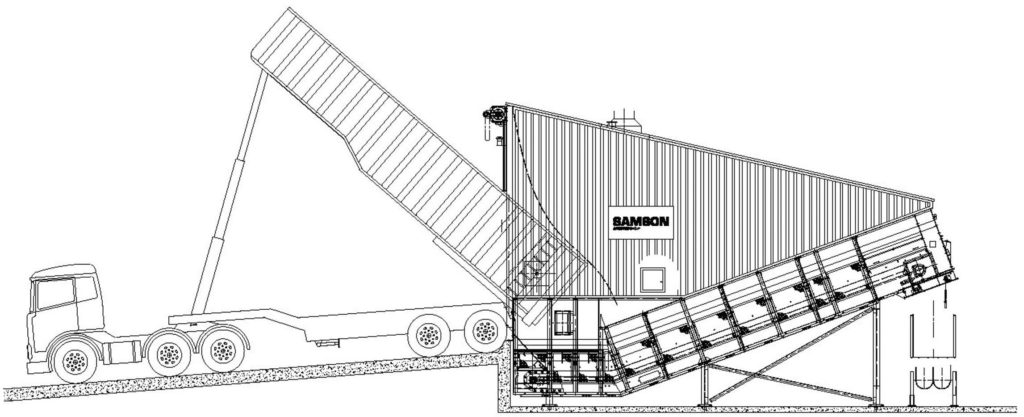

Truck Reception at a Waste Water Treatment Works

- Tipping trucks unload directly through a roller shutter door or flexible entry curtain into a fully profiled steel enclosure

- A truck detection sensor, audible sounder and traffic light signal ensures trucks discharge correctly and safely

- Material unloaded on to wide apron belt. Belt set in motion by truck/material detection sensors

- Material level sensors and surge hopper discharge chute design to regulate material flow to the on-going equipment

Key Features

- Wide apron belt design preventing bridging and clogging

- Flexible side seals to prevent spillage

- Buffer capacity to maintain a steady flow of material

- Environmental controls for dust and odour

- Robust, reliable proven design

Benefits

- Surface installation eliminates underground pits and costly civil works

- Ideal for wet and sticky materials

- Adaptable to changing site requirements

- Easy to maintain

Data

- Samson® Length: 10m

- Samson® Series: 450 Super

- Samson® Output Rate: Typically up to 120m³/hr

- Typical Materials: Sludge Cake

Contact

If we can help you with any further information, please use the contact form to get in touch.

You will receive an immediate automated acknowledgement, and we will respond to your enquiry as soon as possible.

Many thanks

AUMUND. SCHADE. SAMSON.