Alternative Fuels

The Ideal Discharge, Storage and Conveying Technology for a rapidly growing sector

With growing requirements for alternative energy sources, conveying and storage technology needs to keep pace and develop accordingly. The AUMUND Group has been addressing this growth market for many years and has excellent reference installations in numerous areas, such as silo feeding and discharge, stockpiling and reclaim technology, and in the application of mobile conveying and storage solutions.

A huge variety of materials can be used as substitute fuels, for example refuse from livestock farming and foodstuff production, wood chips, shredded plastic rubbish, sewage sludge, tyre chips among others, and all can be conveyed in their various treatment processes with the aid of machines from the AUMUND Group.

An important consideration when handling these materials is the wide variation in flow and storage characteristics. A similarity with solid fossil fuels is seen in the requirement for interim storage and homogenisation, which in many cases is an essential step before treatment.

AUMUND equipment for Alternative Fuels

In the early 90s AUMUND made news by taking over Maschinenfabrik LOUISE in Cologne. In 2006 AUMUND also acquired WTW Engineering in Cologne. Both companies have engineering, patents, production and sales relating to rotary discharge machines and drag chain conveyors. The purchase of these companies and their products gave AUMUND the edge in bringing to market discharge systems such as CENTREX® or LOUISE Rotary Discharge Machines and in driving the development of these products. The acquisition of the spare parts business of Maschinenfabrik Besta & Meyer in 2014 rounded off the product portfolio at that time.

In 2019 AUMUND Fördertechnik began increasing capacity in its engineering team; this signalled the start of new product design in conveying and transportation of alternative fuels.

As AUMUND continues to pursue this strategic path it is now capable of offering an extended range of products for the alternative fuels sector: The offering includes the AUMUND Trailer Docking Station, the AUMUND Moving Floor Conveyor, and the AUMUND Rotating Screw Discharger for the conveying of wood chips, wood pellets, RDF and much more.

AUMUND Trailer Docking Station type TES

The AUMUND Docking Station is particularly suited to truck unloading with autonomous discharge systems such as walking floors and active or moving bottoms. A separate hydraulic aggregate powers these moving floors so that the unloading of the truck is independent of its traction unit. With the aid of dedusting systems on the Station and a curtain, the discharge effected is largely dust free. Screw conveyors on the floor of the Docking Station transport the material sideways to an ongoing conveyor.

The AUMUND Docking Station impresses with its compact, modular and flexible design. Extensive structural requirements are not necessary. Discharge capacities of 200 m³/h with two Docking Stations have already been achieved.

AUMUND Moving Floor Conveyor type SBA

The AUMUND Moving Floor is a reliable conveyor for easy flowing and sticky materials. The Moving Floor consists of special gratings which are individually adapted to the characteristics of the material to be conveyed. The conveyor slats are each powered by a hydraulic cylinder, with individual slats retracting below the material in turn, enabling the complete Moving Floor to bring the material forward in the conveying direction.

The Moving Floor can be installed either on a concrete slab or on steel. Classical applications for the Moving Floor are pre- and interim hoppers for wood chips and bark, sawdust, rubber waste, plastic rubbish, sludge, coal-tar mixtures, refuse from the paper industry and many more. Discharge capacities of 40 up to 300 m³/h have already been achieved.

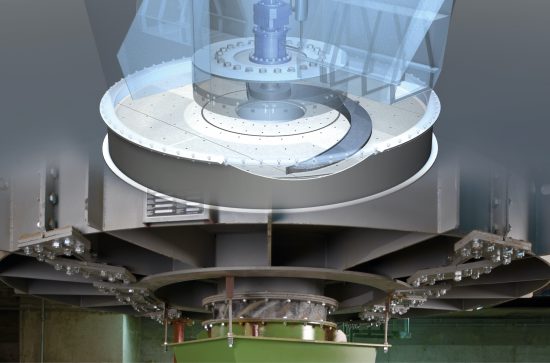

AUMUND Rotating Screw Discharger type RAS

The Rotating Screw Discharger type RAS is a discharge system for dry or damp bulk materials which do not flow easily. The Screw Discharger travels over the silo floor by rotating around the vertical axis of the cone, and conveys the material into the chute beneath the cone.

The Screw Discharger can be adapted to the individual bulk material by variations in the design of features such as the cladding, the teeth, or the pitch of the screw. Screw Dischargers can be installed in steel or concrete silos. Depending on the material properties and the diameter of the silo, conveying capacities of up to 450 m³/h can be achieved. The maximum silo diameter is currently around 25 metres.

AUMUND Drag Chain Conveyor type TKF

- Conveying width up to 2,000mm

- Capacity up to 630 t/h (material dependent)

- Centre to centre distance of 50m and more

- Roller, forged and surface-hardened forged fork-linked chains or roller chains

- Single or double strand chain depending on the application

- Dust-tight components also available in gas and pressure-tight construction

- Different flights available for selection according to bulk material characteristics

- Various conveying arrangement options available

- Material lumps up to 80mm

- Material temperature up to 300 °C (ash)

- ATEX 21/22 possible

AUMUND Bucket Elevators

Throughout nearly 100 years of industrial construction, AUMUND has been a trendsetter in conveying technology and offers products of high technical standard and solutions for a variety of applications wherever conveying and storing of bulk materials is required.

AUMUND Bucket Elevators, tailor made and continuously developed to suit ever increasing plant and process requirements, offer this availability combined with performance, flexibility and service life. With their proven quality, strength and reliability AUMUND Bucket Elevators have become a synonym for efficient vertical transport of any kind of bulk material used as alternative fuels.

Longitudinal Storage with SCHADE Portal Reclaimers

Most biomass fuels reaching modern dedicated or multi-fuel power plants originate in managed forests or from the residues of timber processes. They are generally broken into wood chip (coin sized pieces of wood) and often then dried and extruded into wood pellets.

Depending on the stacking method defined by the type of stockyard, buffer or blending bed, stacking in open stockyards of longitudinal shape is performed with stacker equipment. SCHADE offers the Longitudinal Storage of biomass for example by their Portal Reclaimers. The material is often wood pellets, which are transported long distances by ship, and unloaded by cranes and Eco Hoppers at the port for storage, until they are reclaimed by the SCHADE equipment.

SCHADE Bridge-Type Reclaimers

The maximum blending effect is no doubt achieved with the SCHADE Bridge-Type Scraper combined with the relevant stacking method.

As with all SCHADE Reclaimers, the scraper chain is designed and manufactured to SCHADE standards. SCHADE scraper chains are also fitted with automatic tensioning ensuring equal take-up of by both strands.

SAMSON Biomass Handling Solutions

Since the early 1980s SAMSON Materials Handling has developed a range of mobile materials handling solutions dedicated to the reliable intake, storage and export of general bulk cargoes including many unusual and cohesive materials such as biomass fuels.

Flexibility is at the core of the SAMSON´s product concept; from truck intake using the mobile Samson® Material Feeder, through to mobile stacking and shiploading solutions able to operate from existing berths.

The goal is to deliver this flexibility without compromising performance, highest environmental standards, safety or reliability.

Biomass transfer to Samson® Material Feeder

Walking Floor Trucks have a live bottom in the trailer floor, comprising reciprocating bars that move back and forth beneath the load, and the contents are discharged with a moving bulkhead.

Worldwide there is a vast range of truck styles all dedicated to their specific markets and local customs. Standard end tipping solutions are still by far the most popular but in some markets the side dumper is also used.

For the haulage of wood chip in developed markets, the dedicated trough dumper trailer gives the maximum payload within established regulations. These truck and trailer units are raised on a tipping platform and the wood chip flows through the two bodies exiting via a hinged rear door into the intake system at the processor or power utility.

Samson® Material Feeder Road Intake

Wood chip intake from trucks can be a tricky business. Wood chip tends to block and blind, does not flow easily through inclined chutes and cannot be handled reliably in standard tapered hoppers. In this situation the wide belt Samson® Material Feeder is ideal. Thanks to the wide apron belt design the carrying surface is wide relative to the material depth delivering reliable storage and discharge.

Material is drawn into the Samson® Material Feeder body from the tipping truck in a controlled stream allowing fast truck turnaround, and with minimum free fall, dust generation is mitigated at source requiring much reduced extraction to eliminate fugitive dust nuisance.

Road Intake Stations

For example: at a power plant in Poland, four Samson® Material Feeders receive various types of agri-biomass including wood chip to augment the coal stream and reduce the utility´s carbon footprint. These projects are typical of new CHP plant designed to intake biomass to an established power utility.

Import, Transfer and Transshipment

The SAMSON STORMAJOR® is a universal piece of equipment suitable for stockpiling, barge loading and rail wagon loading, and for the import of wood pellets from small coasters when combined with a grab hopper discharging to existing conveyor systems or storage facilities.

The STORMAJOR® is available with a range of ancillary equipment such as trimming chutes for loading rail wagon or barge, powered travel for easy movement on the quay or stockyard, on-board power for complete autonomy, requiring no shore power or dedicated infrastructure.

Truck to Ship

By integrating two Samson® Material Feeders to a common outloading boom, the fully autonomous Shiploader may receive almost any bulk cargo including wood chip, pellets or grains direct from tipping trucks so eliminating the need for intermediate on-port storage.

Illustrated here, independent mobile Samson® Material Feeders are used in pairs to load a single Shiploader boom allowing two trucks to be discharged simultaneously.

Dust Controlled Bulk Import

The Eco Hopper receives material by grab from up to Cape Size vessels discharged by mobile harbour crane. With the integrated SAMSON dust extraction system and Flex-Flap one way material inlet valve, fugitive dust escape is kept under control.

The Eco Hopper may be either tow travelled or supplied with integral powered travel plus diesel genset for complete autonomy. As with the mobile Shiploader the Eco Hopper may be moved off the berth when not required.

PRODUCTS & SYSTEMS

Flowsheet

Discharge Systems

Bucket Elevators

Chain Conveyors

Apron Feeders

SAMSON® Material Feeder (fixed)

Samson® Material Feeders (mobile)

Pan Conveyors

Telescopic Spouts

Circular Storage

Longitudinal Storage

Stackers, Reclaimers & Combined Machines

Wagon Unloading Systems & Wagon Tipplers

Eco Hoppers

Shiploader