SCHADE NEWS 1//2021 – Products. Projects. Progress.

SCHADE Lagertechnik

The SCHADE Active Harrow improves the flow properties of stockpiled bulk materials

Andreas Junker (Technical Director) SCHADE Lagertechnik GmbH, Gelsenkirchen/Germany

The Active Harrow has been part of SCHADE Lagertechnik’s range of products for many years, as a component both of new machines and equipment conversions. The product has contributed to the success SCHADE enjoys as a manufacturer in this field. With its own designs, in particular for bulk materials which are cohesive and do not flow well, SCHADE has secured itself the reputation of an international expert in the manufacture of Reclaimers and Stackers suitable for materials which are among the most difficult to handle.

In recent years a trend has emerged of quarries being excavated more and more intensively, which means that the materials extracted are not homogenous and have differing characteristics, especially in terms of their flow properties. This is particularly noticeable in the limestone stockpilesof cement plants, where high moisture content in the material combined with a large proportion of extremely fine particles, as small as 5 mm, reduces the extent to which the material will flow. Consequently, the material does not separate easily from the pile and does not readily drop to where it needs to be taken up by the shovels of the Reclaimer for transfer to the discharge conveyor.

Active Harrow – Achieving the required reclaim capacity

Frequently, values which are contractually guaranteed are based on material parameters such as moisture content, particle sizes and their proportional distribution. As it is difficult for a supplier to claim at a later stage that the material properties no longer correspond to the contractual specifications, a conventional harrow design is not the right equipment for the job.

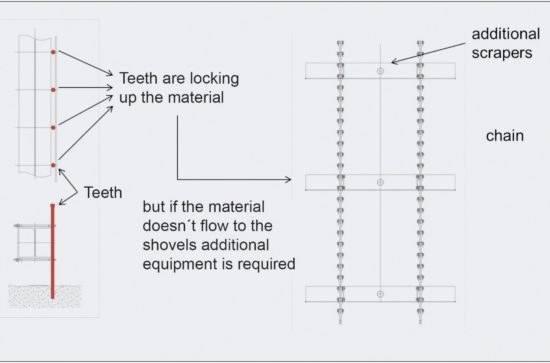

In order to achieve the contractual reclaim capacity, a thin slice of the material needs to be separated from the stockpile and to fall into the shovels of the Reclaimer. The prerequisite for this is that the bulk material on the pile flows freely. If the material does not flow freely by itself, the SCHADE Active Harrow agitates the material so that the slice can bedischarged. The Active Harrow principle is to attach small scrapers to a conventional harrow so that the bulk material is released into the shovels continuously.

Applications for Bridge-Type Reclaimers

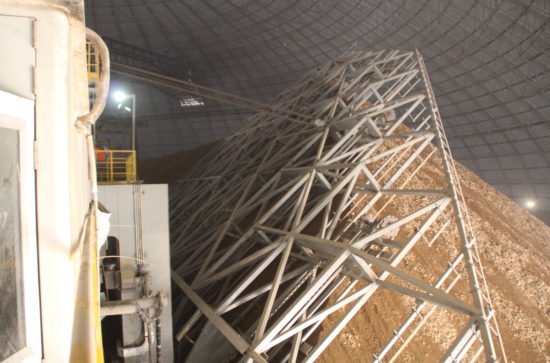

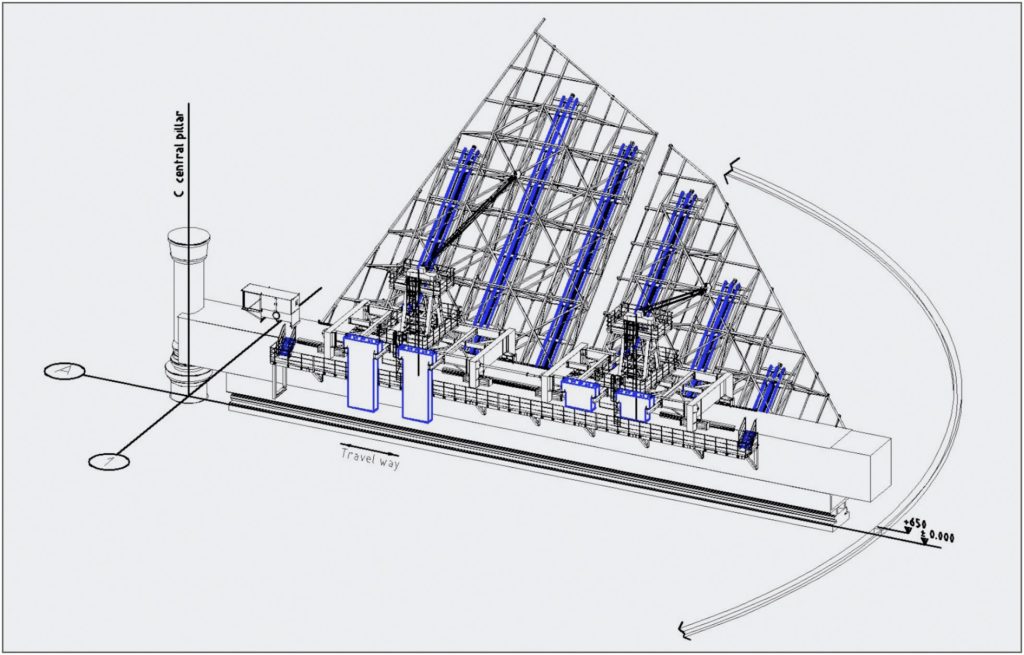

Unlike Full- or Semi-Portal Reclaimers, which remove the bulk material from the side of the stockpile, Bridge-TypeReclaimers, whether they are machines which travel autonomously or are installed in circular storage, frequently encounter problems with bulk material not flowing freely or not coming away from the pile easily. Unlike Cantilever Reclaimers,which travel parallel to the stockpile and loosen the bulk material directly with their shovels, Bridge-Type Reclaimers are constructed to remove material from the cross section of the pile. The Bridge-Type Reclaimer reclaims the pile gradually from the front, evenly across its complete width and height. From a production point of view this is particularly important inthe cement industry, as blending of the material is required. The reclaiming method of a Bridge-Type Reclaimer allows the introduction into the production process of the complete range of particle sizes found throughout the whole of the stockpile cross section.

The bulk material volume, calculated by the width of the pile and the insertion depth of the harrow into it, multiplied by the bulk material density, gives the reclaim capacity in tph of the machine. As longas the bulk material flows freely, sufficient filling of the shovels will be maintained and therefore the required reclaim capacity will be achieved. If, however, the bulk material ceases to flow because the moisture content is too high or the particle sizesare too small, the material loosened by the harrow prongs stays on the pile and agitation of the bulk material is imperative. On a Bridge-Type Reclaimer this is the function of the Active Harrow.

Construction of the Active Harrow

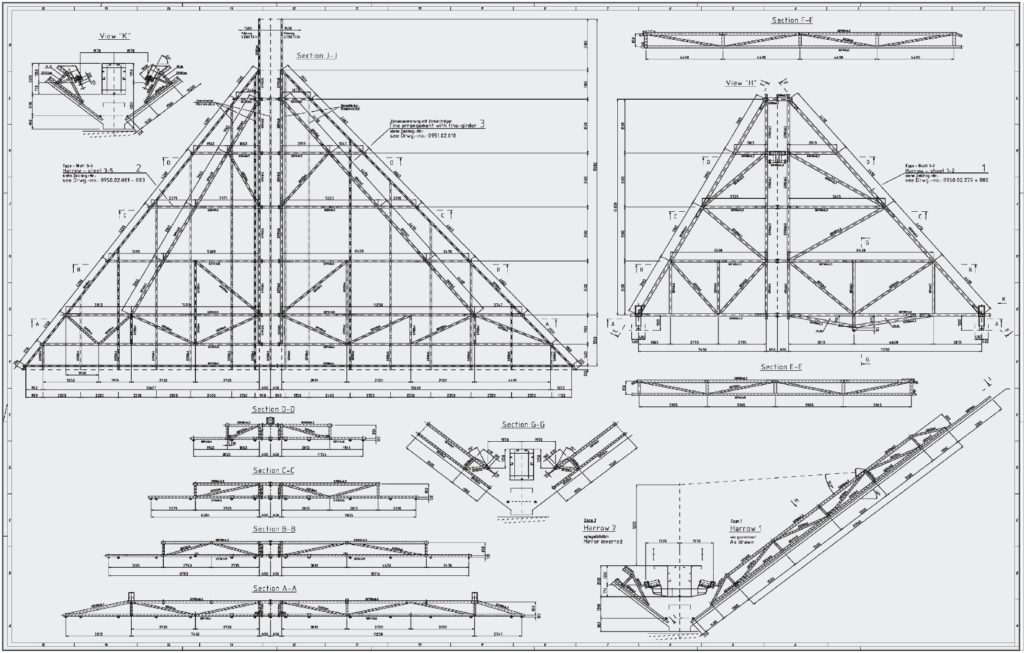

An Active Harrow is a conventional harrow with the addition of several smallintegrated scrapers. The basic functioning of an Active Harrow can be described simply as follows: Firstly the Harrow loosens clogging bulk material from the stockpile with the aid of harrow prongs. As the loosening is still not enough to make the material flow by itself, the small scrapers help the material into the shovels of the scraper chain of the reclaiming machine.

SCHADE Active Harrows are always double layered. The lower layer, nearer to the stockpile, has the prongs fixed to it, is non-load bearing and guides the scraper chain. The upper layer serves as the load bearing structure, absorbing all the loads from the harrow system. The scrapers are installed between the two layers, which is how the height of the Active Harrow is determined.

Bulk material properties change

During the 30 years or more expectedlifetime of a machine, the characteristicsof the bulk materials can often vary fromthose given originally as the basis for the design. This can lead to the machine no longer being able to achieve its capacity, because it was designed for different circumstances. Adapting the equipment tothe new requirements can be costly for the operator. SCHADE can help with advice to customers in such situations to find the best solution to the problem.

Conversion of a conventional harrowinto an SCHADE Active Harrow

The conversion of a conventional harrow to an Active Harrow is possible, but significant modification of the supporting structure of the machine is required. In spite of this, a conversion can be a viable option, especially in a Circular Storage where the Bridge-Type Reclaimer with its harrow is only a partial component of the equipment.

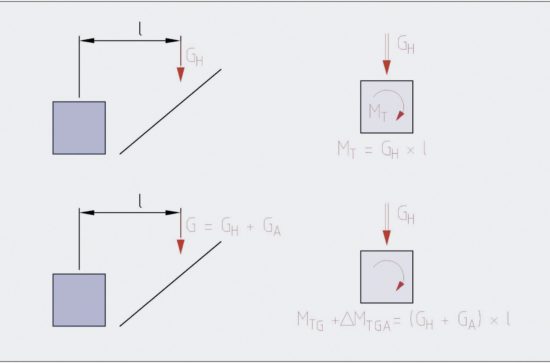

In this case a conversion is less costly than the purchase of an entirely new machine, and also takes less time to complete. Fora stand-alone Bridge-Type Reclaimer the construction of a new machine is likely tobe the more cost-effective option. Because the Active Harrow is considerably heavier due to the small scrapers and their support structure, the whole machine is subject to additional loads. The existing harrow is usually not able to support these loads so a new one has to be calculated and designed. Also the mountings of the harrow, which can either be flat irons as tension rods or ropes from a winch system, are subject to greater loads and must be re-dimensioned accordingly.

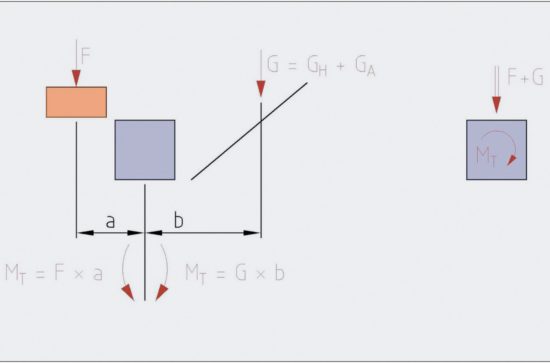

If the harrow is attached to one side ofa bridge girder, the counterweight must be increased in order to minimise both torsion in the bridge girder and resulting additional support loads. If there are harrows on each side of the bridge girder this is not necessary because of theequal distances to the centre of gravity of the harrows. In both cases, however, depending on the inclination of the harrow, torsion forces will be present because the counterweight or the harrow on the other side cannot offset all harrow positions.

Once the modified weights of the harrow and the counterweight have been determined, the bridge structure must be examined from a statics and design point of view, in order to establish whether thedimensioning of the bridge is still sufficient. In general the bridge is a large metalbox or framework structure. It is often sufficient to increase the strength of the bridge by adding bracing elements such as additional bulkhead plates or stiffening struts to the body of the bridge, and modifying the connections.

For the modification of a conventional Bridge-Type Reclaimer the trolleys and drives should also be examined, to determine whether the permissible wheel loads will be exceeded by the increased weight of the equipment. As it is not possible to exchange the rails, the number of wheels often needs to be increased, which again causes considerableadditional design work. This is also the case for a bridge in Circular Storage.

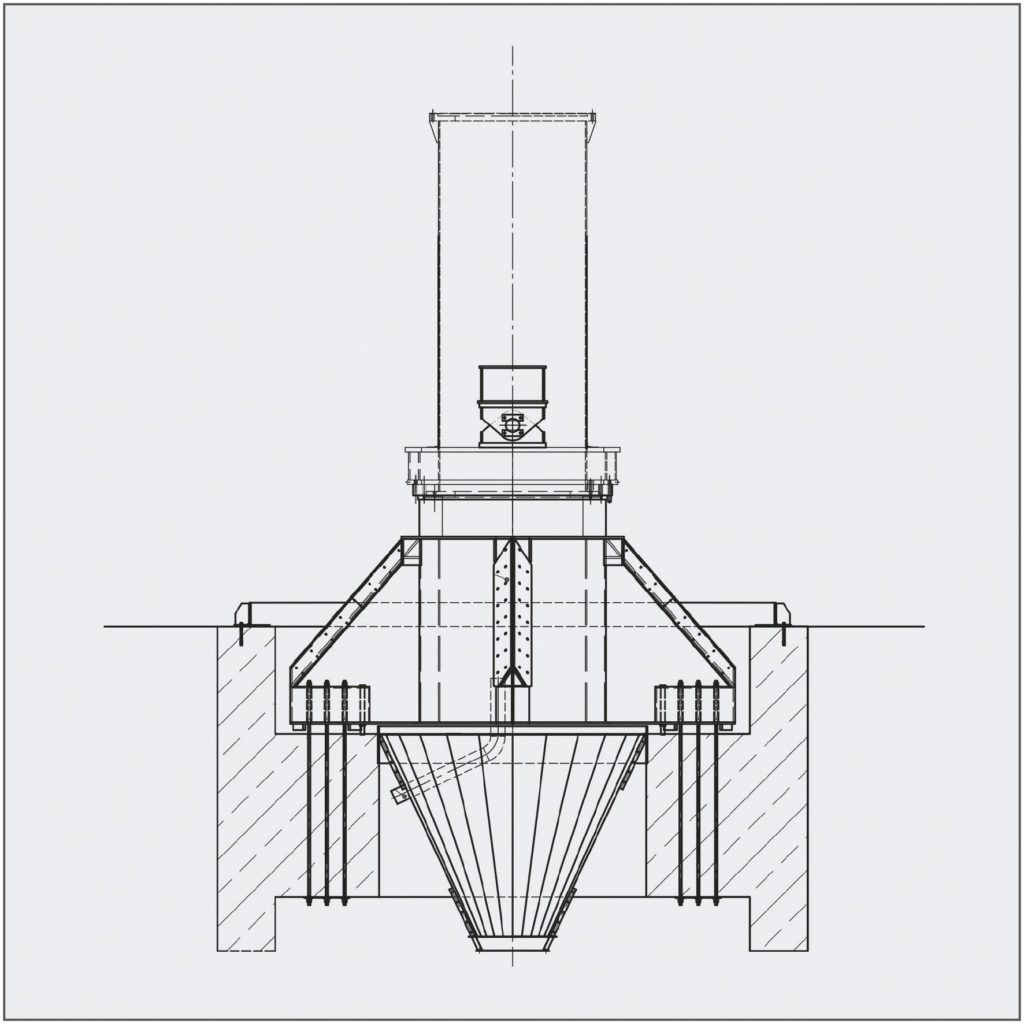

When modifying a Bridge-Type Reclaimer which works as part of a Circular Storage, the previously mentioned load increasing factors could impact the slewing ring, i.e. the connection between the bridge and the central column, to the extent that itwill require replacement. The anchoring of the central column to the foundations also needs to be checked but the additional loads can usually be absorbed at this point.

Summary

Bridge-Type Reclaimers with harrows are important and essential reclaiming equipment for bulk materials stockpiles where homogenisation of the material is required for the ongoing process.

An Active Harrow makes it possible to discharge even non-flowing material with a Bridge-Type Reclaimer, and to achieve the fulfilment of the two conditions usually contractually required by a customer for its process: the specified amount of material and its degree of homogenisation.

SCHADE Lagertechnik GmbH has converted conventional harrows to Active Harrows on many occasions in recent years, often on other manufacturers’ equipment. These conversions are frequently combined with a capacity increase. By supporting its customers from the sales phase right through to commissioning, SCHADE has built up a leading market position for itself in this technology.

The SCHADE Active Harrow in operation: examples of conversions

By converting to an Active Harrow from SCHADE, plant operators can upgrade their equipment to such an extent that it can regain its originally planned capacity. Here are two examples of projects which were carried out by SCHADE to the utmost satisfaction of the operators:

1. Conversion of a Circular Storage with Bridge-Type Reclaimer for limestone in Tula, Russia

A Bridge-Type Reclaimer integrated into a Circular Storage by another manufacturer was not fulfilling its contractual capacity. This was mainly due to the extremely challenging bulkmaterial properties such as high moisture content, relatively small particle sizesand a very large temperature range, from-30°C to +30°C. The low temperature in connection with the high moisture content of the bulk material caused compacting of the material, and the high temperature made it extremely sticky.

The originally installed conventional harrow could not overcome the challenge, being unable to detachthe material from the stockpile, so the capacity was not achieved. The harrow also became misshapen by the frozen, hard, tough and sticky bulk material, and the structure of the harrow was damaged.

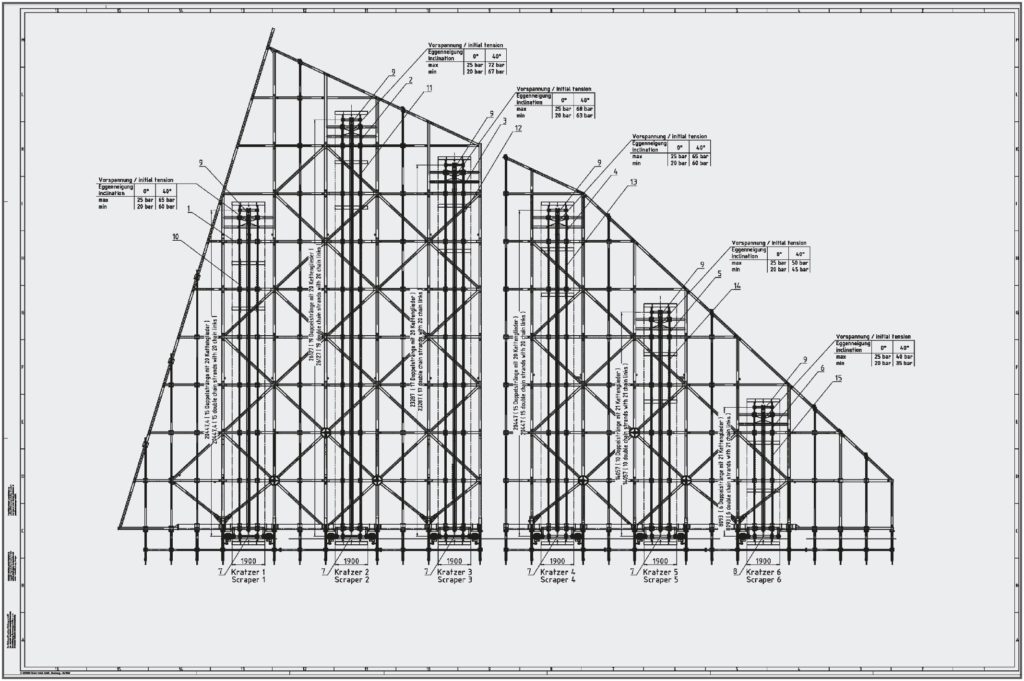

SCHADE completely redesigned the harrow as a new Active Harrow with five integrated scrapers. The Harrow was equipped with sufficient bracings to keep any distortion to a bare minimum.

2. Conversion of a Circular Storage with Bridge-Type Reclaimer for Iimestone at Cemindo Gemilang in lndonesia

Here too, a Bridge-Type Reclaimer integrated into a Circular Storage by another manufacturer was not achieving its contractual capacity. The reason was the extremely moist material, a mixture of Iimestone and red clay, which created asticky consistency. When left for Ionger periods an the stockpile the material also hardened.

SCHADE replaced the originally installed conventional harrow with an Active Harrow, which was designed in sections because of its size, approx. 45m wide, and its weight. The weight of theconventional harrow was approximately100 t, but the Active Harrow weighed almost 240 t. As there was a harrowonly an one side of the bridge girder, the counterweight had to be adapted. The particular challenge of this proJect was the existing bridge structure, which had been designed in the shape of a U-frame and had to be retained as such. This made it necessary to re-positionthe Active Harrow an this bridge girder.Because of the increase in weight of the harrow and counterweight it was necessary to reinforce the body of the bndge with approximately 60 t ofadditional bracing.

Contact

If we can help you with any further information, please use the contact form to get in touch.

You will receive an immediate automated acknowledgement, and we will respond to your enquiry as soon as possible.

Many thanks

AUMUND. SCHADE. SAMSON.