SAMSON NEWS 1//2020 – Products. Projects. Progress.

SAMSON Materials Handling

AUMUND delivers SAMSON Eco Hopper EH 45 and EH 60 worldwide.

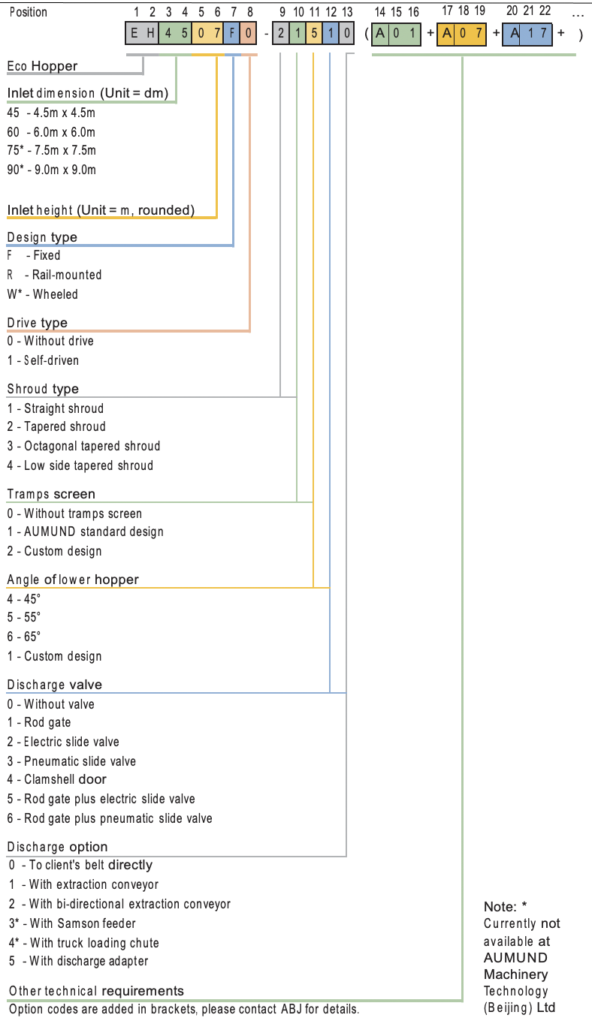

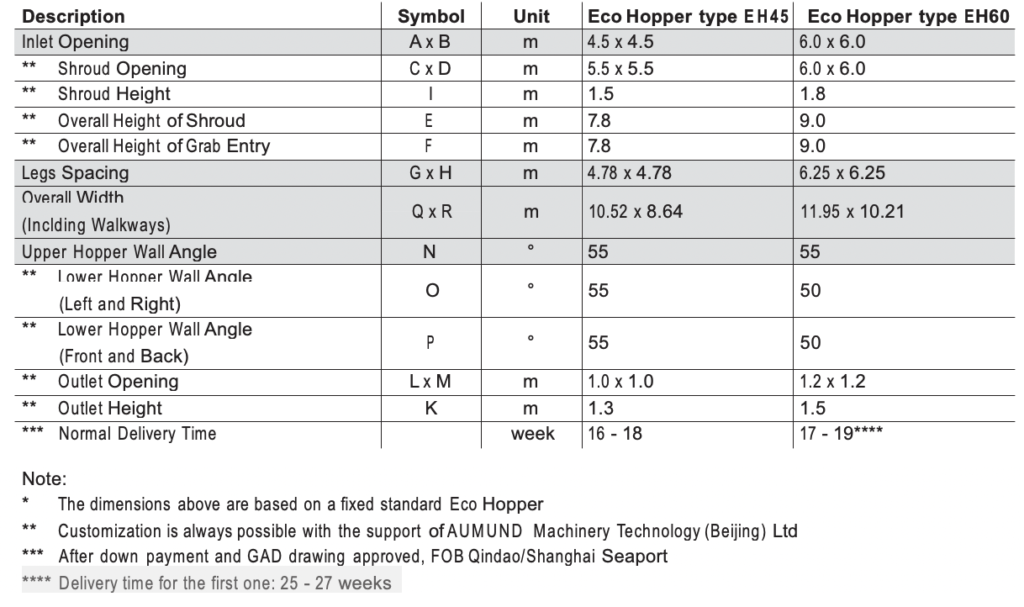

Cost-effective and short delivery time. From now AUMUND Machinery Technology (Beijing) Ltd offers worldwide two types of SAMSON Eco Hoppers designed on a new economical and technical concept by saving all advantages and benefits of the product. The standardization of the Eco Hopper type EH45 (inlet 4.5×4.5m) and type EH60 (inlet 6.0×6.0m), available on rails, wheeled or fixed, enables a more effective assambling of the components, a lower price level and shorter delivery times. EH 45 and EH 60 will be produced in China and can be ordered worldwide from AUMUND China directly.

The SAMSON Eco Hopper series applies a variety of dust and environmental control technologies, such as crosswind turbulence reduction system, Flex-Flap dust seal system, integral cartridge dust filter Units, etc. It is an economical and ecologically sensitive solution fulfilling all needs for the efficient import of dry bulk cargoes.

The Hoppers are designed to suit the characteristics and flow properties of virtually any bulk material such as Clinler, Bauxite, Limestone, Iron Ore, Gypsum, Slag, Coal, and many others. Rates to 3000 tons per hour may be achieved subject to the grab crane performance. The open size and height of top shroud, the angle of lower hopper, the thickness and the type of wear material are all customized for the client’s specific product and process.

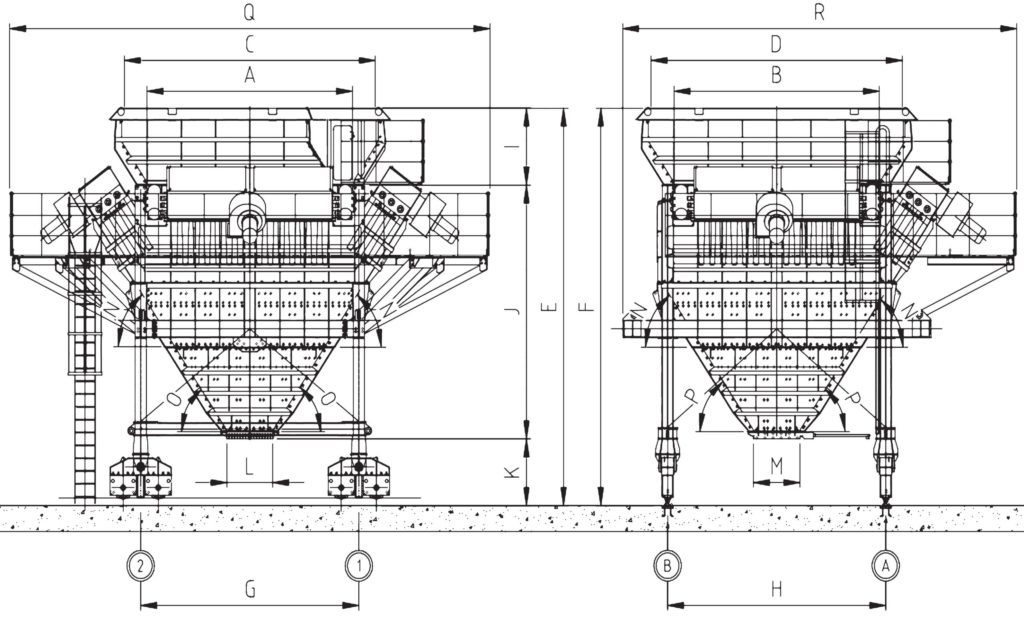

Eco Hopper Overall Dimensions

Dimensions in principle*

Effective Dust Control

Technologies Top Shroud – Crosswind Turbulence Reduction System

The Eco Hopper includes a top shroud designed to allow for the crane Grabs to be lowered within the reception area before opening. This system is designed to reduce the wind turbulence above and within the Inlet Shroud which is commonly caused by cross winds. As a result this system reduces the filtration airflow requirements.

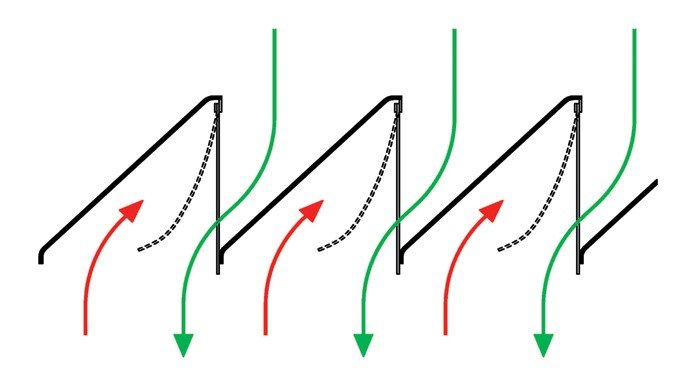

SAMSON Flex-Flap System – One-way Non-return Valve System

Top Shroud Material Flow The Flex-Flap was first developed by AUMUND based on the Burnley Baffle principle, which is a mechanism similar to a one-way non-return valve composed of steel and rubber, and used to reduce the volume of air necessary to control dust from the opening grab and displaced air from material falling into the inner hopper below.

Cartridge Dust Filter Units – Efficient and Compact Dust Collector

The SAMSON Eco Hopper employs a fully integrated dust filtration suction system operating below the inlet grating for fugitive dust control. Individual dust filter units are integrated into three sides of the Hopper only. The highly efficient SAMSON Eco Hopper design means that the waterside of the Hopper (closest to the vessel) does not require a filter unit. This feature means that the SAMSON Eco Hopper is extremely compact and offers:

- A reduced distance for the grab to travel

- Resulting in faster grab cycle times • Reduced grab operating costs

Discharge Options

To Client‘s Belt directly

Discharge from the Eco Hopper may be direct to a belt conveyor for a fixed installation. In this case the bulk material is reclamed by a gravity discharge unit (rod gate) which permits to feed the material onto the conveyor at the requseted output rate.

With Extraction Conveyor

The SAMSON Eco Hopper can be mounted onto tracks to match the mobile crane on some ports. In this case a separate extraction conveyor integrated on the Hopper is often equipped. The conveyor can be designed for single or bi-directional discharging according to the client‘s material handling process and the layout of the quay belt conveyor.

Structure of the Product Number

Contact

If we can help you with any further information, please use the contact form to get in touch.

You will receive an immediate automated acknowledgement, and we will respond to your enquiry as soon as possible.

Many thanks

AUMUND. SCHADE. SAMSON.