AUMUND NEWS 2//2020 – Products. Projects. Progress.

AUMUND Fördertechnik

Your Partner in Metallurgy Worldwide.

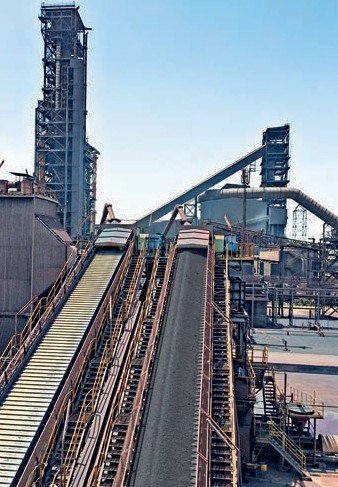

AUMUND Group technologies provide solutions for numerous conveying applications in ferrous and non-ferrous metallurgy as well as in foundries.

Specific expertise and an excellent position in the market are in evidence in specialized conveying equipment adapted to materials at temperatures of up to 1100 °C, optionally incorporating the use of inert gas, as wellas in technology for cooling iron briquettes and similar materials without damaging them.

AUMUND equipment for metallurgy

For the different process stages in Iron and Steel plants AUMUND provides solutions and products for

- Conveying and storing of coal, iron ore or limestone

- Conveying of DRI, HBI, HCI, Fe-Pellets, Fe-Sinter and coke up to 1100 °C

- Conveying in inert atmosphere or seal gas

- Conveying and smooth cooling of HBI

- Additional cooling of Fe-Pellets orFe-Sinter

- Conveying of various kinds of hot and cold scrap or residuals

- Conversions or retrofits of existing material handling equipment

Direct reduction process

AUMUND has developed innovative conveyors to take hot DRI (direct reduced iron or sponge iron) either from the MIDREX shaft furnace or in other processes from the rotary hearth, rotary furnace or fluidized bed. This means sfor example that the material can be directly charged into an electric-arc furnace (EAF) while it is still hot. Several specialapplications have been developed for this technological environment. AUMUND’s hot material and cooling conveyors are unmatched internationally.

Sintering plants

Sinter is conveyed at temperatures of up to 1100 °C from the sintering plant to the cooler, or after the cooler if the material is still too hot for standard belt conveyors.

Main advantages and characteristics of the AUMUND sinter conveyor:

- Lower energy requirement and lower noise emissions, therefore better working conditions in comparison to vibrating conveyors

- As relative motion between the sinter and the conveyor is eliminated, wear and sinter break-up are reduced

- The precise, overlapping design of the conveyor pans minimizes spillage

- Low maintenanc

Modern sinter shaft coolers utilize energy from the hot sinter and are connected by insulated AUMUND sinter conveyors in order to optimize energy recovery.

Pellet cooling

In cases where the main cooler does not cool the pellets sufficiently, an AUMUND conveyor acts as extended cooling line. It is designed with special air flow features and dedusting at the inlet. Thus additional air cooling of hot pellets is provided.

HBI cooling

Controlled, slow cooling down (“smooth cooling” rather than in a quenching tank) of the HBI on the patented AUMUND cooling conveyor with a mixture of mist and air for high quality briquettes.

Main advantages and characteristics of the AUMUND HBI cooling conveyor:

- Cooling with the aid of a defined water mist but with low water consumption

- Avoidance of sludge formation

- Clean environment due to closed system

- Improvement of the HBI quality by slow cooling

SCHADE High Performance Stockyard Solutions

SCHADE Lagertechnik GmbH is a global market leader in designing and supplying stockyard technology such as longitudinal and circular stockyards, blending beds, tripper cars, bridge- and portal-type stackers and reclaimers as well as wagon unloading systems.

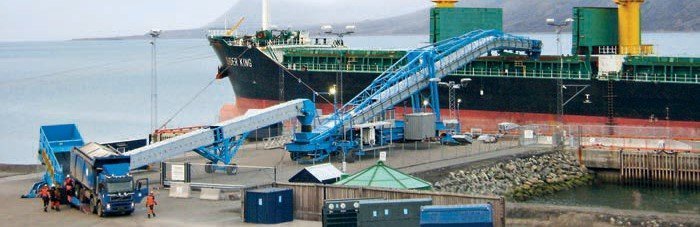

SAMSON Mobile Solutions

SAMSON Materials Handling Ltd. is expert in mobile bulk materials handling equipment for surface installation: from truck unloaders, to shiploaders, rail and barge loaders, ecological import hoppers and mobile stockpiling equipment. Hardworking equipment designed for rapid set-up and continuous high performance.

AUMUND Group – Spanning the Globe

The AUMUND Group is a specialist in the field of conveying and storage equipment for a wide range of bulk materials.Its particular strength are technically sophisticated and extremely reliable solutions for handling bulk materials with all kinds of characteristics, even hot, abrasiveor sticky. More than 18,000 machinery installations in over 120 countries bear witness to the excellent reputation and market position of the Group.

The manufacturing companies AUMUND Fördertechnik GmbH (Rheinberg, Germany), SCHADE Lagertechnik GmbH (Gelsenkirchen, Germany), SAMSON Materials Handling Ltd. (Ely, England), as well as AUMUND Group Field Service GmbH and AUMUND Logistic GmbH (Rheinberg, Germany) are consolidated under the umbrella of the AUMUND Group. The global conveying and storage technology business is spearheaded through a total of 19 locations in Asia, Europe, North and South America, a global network of around 80 agents, and five warehouses in Germany, USA, Brazil, Hong Kong and Saudi Arabia.

Contact

If we can help you with any further information, please use the contact form to get in touch.

You will receive an immediate automated acknowledgement, and we will respond to your enquiry as soon as possible.

Many thanks

AUMUND. SCHADE. SAMSON.