Consultation & Planning

The basis for conveying and storage technology solutions in bulk materials industries is the ability to give advice to customers relative to the respective technology of their application, and to plan and design the equipment accordingly.

Consultation and planning are part of the overall concept of an order, but they can also be offered as a stand-alone service. This initial and extremely important phase of a project builds customer confidence and often results in subsequent orders for machines or more extensive technological solutions.

Since the 70s AUMUND has been supporting customers all over the world with consultation and planning, with a focus mainly on conveying and storage of bulk materials. Over these decades AUMUND has developed particular expertise in the cement industry. Economics, optimisation of conveying routes, structural dimensions, storage capacities, available space and surface area are all aspects which are taken into consideration in consulting and planning within the constraints of the existing operation.

Storage in Silos

The planning of the best location for storage of clinker, at the required capacity and with the appropriate conveying technology to feed and discharge, can be advantageous for the operator in terms of capital investment and later in sustainability of production. This is why AUMUND develops tailor-made and economically sound solutions for state-of-the-art clinker storage technology, either with concrete or steel silos, or in circular storage.

Mill Feeding, Conveying Technology, De-dusting, Loading and Unloading

Supply packages from AUMUND consist not only of the planning and design of individual components, but also the supply of the complete conveying technology, de-dusting equipment, steel structure, storage technology and sundry accessories such as chutes, distribution stations, truck or wagon loading.

Greenfield Projects

Involving AUMUND expertise at an early stage in greenfield or brownfield projects, to integrate the design and application of the conveying and storage technology into a cost-effective and ecological overall concept, is becoming more and more popular with general contractors and customers. Qualified site service personnel, either from company headquarters or from the international subsidiaries, are available for supervision of installation and commissioning.

For SCHADE, consulting and planning are the basis of every project for Stockyard and Blending Bed solutions and for designing Stackers, Reclaimers or combined machines.

Longitudinal Storage

Longitudinal stockpiles are very often created where there is a necessity to store large volumes of bulk materials in between individual stages of a process. In addition, such buffer facilities are used for the homogenisation or mixing of bulk materials with different material characteristics. SCHADE offers ideal solutions for both applications.

Inventory Storage

Stockpiles are the simplest form of bulk materials storage. They serve as inventory or buffer storage and are an important link between material provision and production. Where it is necessary to protect from weather conditions or where environmental concerns make it a requirement, stockpiles are also constituted inside buildings. For both scenarios a range of typical stockyard arrangements has become established.

Blending Beds

In many industrial processes a homogenous mixture of the raw materials is an important factor. This function of mixing or consolidation can be carried out on stockyards with blending bed technology. The best possible mixing effect is achieved by reclaiming from the front end of the pile with a Bridge-Type Reclaimer, if the Stacker has built up the pile so that its cross section has as many layers as possible of the same material. Just like inventory storage, blending bed technology can also be installed in storage buildings.

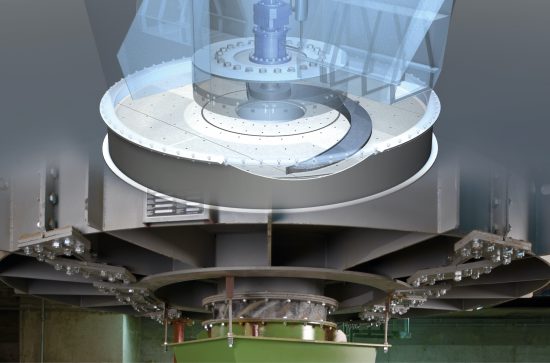

Circular Storage, Inventory Storage

The constraints of having high volume storage requirements but with restricted space available are increasingly being resolved by circular storage concepts. SCHADE is one of the forerunners in this development and has many excellent international references to show for it.

Circular storage of inventory offers a combination of relatively small space requirements and high storage volumes. It has become one of the major areas of expertise of SCHADE Lagertechnik in recent years.

Circular Storage, Blending Beds

SCHADE develops recognised concepts all over the world for Blending Beds with optimum mixing or homogenisation of the stored bulk material, by equipping the plants with combinations of Stackers and Bridge-Type Reclaimers.

The Stacker constitutes the stockpile as a Blending Bed, and the Bridge-Type Reclaimer homogenises the material during reclaiming. It collects the bulk material which is continuously loosened by the harrow scraping along the end face of the pile. The rotating scraper chain, which is mounted on a torsion-resistant supporting structure, conveys the material into a central discharge chute. Operation is monitored and controlled by a programmable logic controller (PLC) and is fully automated.

The SAMSON brand is known for mobile loading and unloading systems such as Shiploaders, Eco Hoppers and Material Feeders, which are extremely flexible in operation. The main areas of application are in ports and terminals and in many key industries such as cement, raw materials processing, metallurgy, power plants and in the conveying of alternative fuels.

Every enquiry is launched with a consultation and with project-specific planning, in order to develop the best technical solution, which is also cost-effective and ecological, wherever in the world it is to be operated.

Products & Systems

Discharge Systems

Bucket Elevators

Chain Conveyors

Apron Feeders

SAMSON® Material Feeder (fixed)

Samson® Material Feeders (mobile)

Pan Conveyors

Telescopic Spouts

Circular Storage

Longitudinal Storage

Stackers, Reclaimers & Combined Machines

Wagon Unloading Systems & Wagon Tipplers

Eco Hoppers

Shiploader

STORMAJOR®